TM 9-2350-261-34

R E P A I R

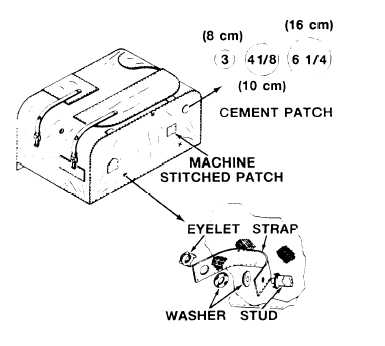

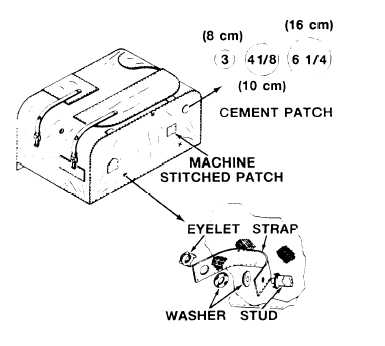

N O T E

The materials used to make a cement

patch are adhesive, round patch of vinyl

coated nylon cloth, roller, board, wire

brush, and soft bristle brush.

9.

10.

11.

Select a patch that overlaps damaged area

with a margin of at least 3/4 inch (19 mm)

on all sides.

Place board under damaged area

working surface.

Buff patch and damaged area of

wire brush.

for a flat

fabric with

with your skin.

W A R N I N G

Adhesive is flammable and

can injure you. Keep it

away from heat, sparks,

and open flame. Avoid re-

peated or prolonged breath-

ing of vapors. Avoid contact

12.

13.

14.

15.

16.

17.

Center patch over damaged area. Apply

adhesive to patch and batch edge, making

a circle on fabric with soft bristle brush.

Lift patch and apply adhesive to area of

fabric inside adhesive circle.

Allow adhesive to dry until tacky (about

10 minutes).

Press cemented surfaces together firmly with

roller while tacky.

Seal by wiping edge of batch with soft

bristle brush.

Repair webbing using machine stitching as

shown below. Install webbing in a square

pattern with diagonal stitches from corner

to corner.

18. Repair hardware as shown in the following

figure. See FM 10-16 for installation of

eyelets and studs with washers.

N O T E

Use lock stitching when you install

patches, flaps, and straps or repair open

seams.

Use a polyester thread and

smallest needle you can to make weather-

proof seams. Allow 5 to 7 stitches per inch

(3 cm). Backstitch all thread breaks at

least 1 inch (3 cm). Backstitch all ends at

least 1 inch (3 cm), except where ends are

turned under in a hem or seam or held

down by other stitching. Maintain thread

tension so stitching is tight and lock is

fixed firmly in center of material. Trim all

ends. Take care when restitching to make

a new stitch line.

12-2