TM 9-2350-261-34

C H A P T E R 12

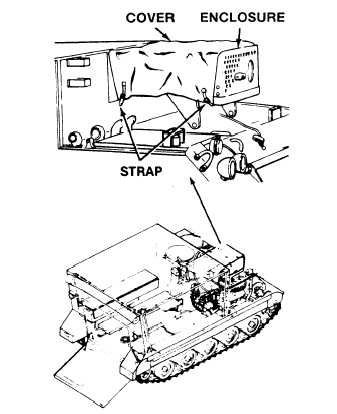

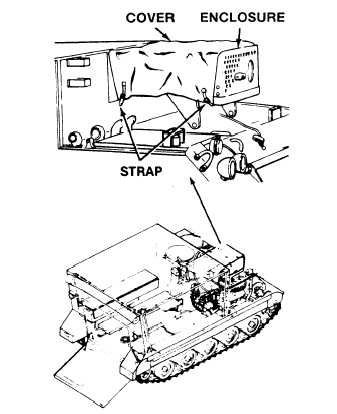

M A I N T E N A N C E O F A U X I L I A R Y P O W E R U N I T C O V E R

REPAIR AUXILIARY POWER UNIT COVER (M577A2 ONLY)

DESCRIPTION

This task covers:

Inspect (page 12-1).

Repair (page 12-2).

INITIAL SETUP

Tools:

References:

Sewing Machine (Item 82, App B)

See your -10

FM 10-16

Materials/Parts:

Adhesive sealant (Item 2, App C)

Equipment Conditions:

Vinyl coated nylon cloth (Item 15, App C)

Cover removed from carrier (see your –10)

Personnel Required:

Track Vehicle Repairer 43M10

INSPECT

7.

1.

2.

3.

4.

5.

6.

Check fabric. Weak or torn areas may be

repaired by a cement patch or machined

patch. All material used to repair the cover

must be the same as the original material.

Check strength of fabric. Grasp a small fold

of fabric between thumb and forefinger of

each hand, gripping it closely so tips of

forefingers touch. Tug material several times.

If it does not rip, it is reparable. If it tears

on first tug, test several areas for extent of

wear. Weak sections must be replaced.

Check for spots and stains. Nonwear spots

and stains are all right if fabric has been

brushed clean. Repair fabric where fabric

strength has been weakened by mildew,

sap, or dirt stains.

Check fabric. Repair opened seams, runoff

stitching, and broken threads. Restitch worn

stitching.

Check webbing straps. Repair or replace

worn, frayed, or torn straps.

Check buckles. Replace buckles that are bent,

broken, or missing.

8.

Check for slide fasteners (zippers). Replace

zippers that are rusted or do not work

correctly.

Check eyelets, washers, and studs. Replace

parts that are bent, broken, or missing.

GO TO NEXT PAGE

12-1