TM 9-2350-261-34

FLUSH RADIATOR

REPAIR

8.

9.

10.

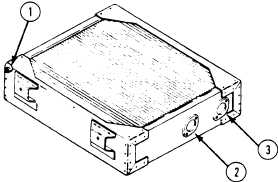

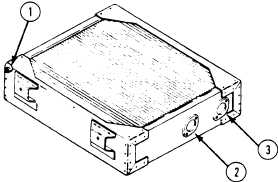

Plug auxiliary tank connection opening (1).

16.

Use radiator test plug set.

Connect water supply to radiator outlet

opening (2). Use radiator test stand.

17.

Flush radiator until water from radiator

inlet opening (3) runs clear.

18.

19.

20.

21.

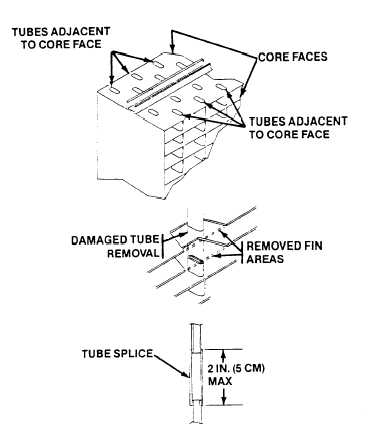

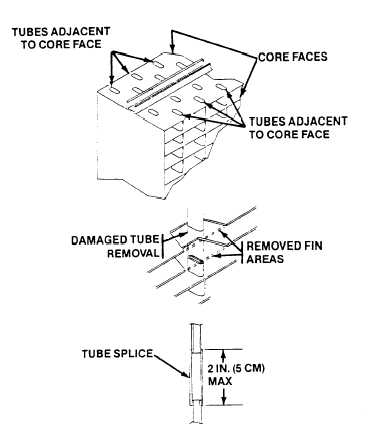

Resolder cracked solder joints and splice

damaged tubes. If necessary to repair tube

damage near end tanks, disassemble

radiator (steps 22 and 23).

Tube splicing shall be limited to no more

than two tubes adjacent to the core face on

either side.

Removed areas of fin shall not exceed 6-1/2

square inches (42 sq cm) per side, per any

tube repair. Length of tube splice shall not

exceed 2 inches ( 5 cm). Tube blockage is not

allowed.

Heat solder repair of the upper and lower

tanks, side brackets, and inlet and outlet

openings is allowed.

Heat soldering of a core shall not exceed a

linear length of 8 inches (20 cm) for any

one core assembly.

Fin straightening is allowed.

11.

12.

13.

14.

15.

TEST RADIATOR FOR FLOW

Plug auxiliary tank connection opening (1).

Use radiator test plug set.

Using radiator flow test machine, connect

supply hose to radiator inlet (3).

Connect return hose of test machine to

radiator outlet (2).

Flow test radiator at 70–80 gallons

( 276–292 liters) per minute. See

TM 750-254.

If pressure drop is more than 4 psi

(28 kPa), disassemble radiator and rod out

radiator core (see steps 22–30).

GO TO NEXT PAGE

5-3