TM 9-2350-261-34

R E P A I R R A D I A T O R

DESCRIPTION

This task covers:

Clean and Inspect (page 5-2).

Test Radiator For Leaks (page 5-2).

Flush

Radiator (page 5–3).

Test Radiator For Flow (page 5-3).

Repair (page 5-3).

Rodding (page 5-4).

INITIAL SETUP

Tools:

Metal Worker’s Tool Kit (Item 61, App B)

Industrial Goggles (Item 37, App B)

Radiator Flow Test Machine (Item 34, App B)

Radiator Test Plug Set (Item 75, App B)

Radiator Test Stand (Item 91, App B)

Scratch Wire Brush (Item 11, App B)

Utility Apron (Item 5, App B)

Materials/Parts:

Solder (Item 80, App C)

Soldering flux (Item 77, App C)

Personnel Required:

Metal Worker 44B10

References:

See your -20

TM 750-254

TB SIG 222

TM 9-237

Equipment Conditions:

Radiator removed from carrier (see your -20)

CLEAN AND INSPECT

TEST RADIATOR FOR LEAKS

1.

2.

Clean radiator. See TM 750-254. Use safety

goggles, rubber gloves and rubber apron.

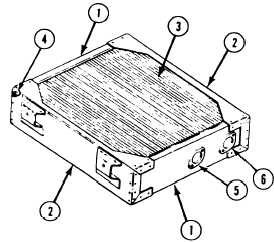

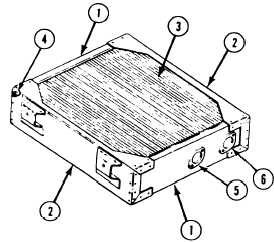

Inspect radiator. Check upper and lower

tanks (1), side brackets (2), tubes and

fins (3). If damage is minor, pressure test

radiator. If damage is major, see repair

instructions to determine if radiator can be

repaired.

3.

4.

5.

6.

7.

W A R N I NG

Radiator can burst if over

pressurized. Do not exceed

25 psi (172 kpa) air pres-

sure.

Ensure radiator is

submerged before applying

air pressure. Always wear

safety goggles.

Plug auxiliary tank connector opening (4).

Use radiator test plug set.

Plug radiator outlet opening (5). Use radiator

test plug set.

Connect regulated air supply from radiator

test stand to inlet opening (6).

Submerge radiator in radiator test stand.

Apply 20–25 psi ( 137–172 kPa) air pressure

to radiator.

If air bubbles appear, repair radiator

(see steps 16-21).

5-2