TM 9-2350-261-34

R E P A I R R A D I A T O R A U X I L I A R Y T A NK

INITIAL SETUP

Tools:

References:

Metal Worker’s Tool Kit (Item 61, App B)

See your -20

Degreaser (Item 22, App B)

TM 43-0139

Radiator Test Plug Set (Item 75, App B)

TM 9-237

Radiator Test Stand (Item 91, App B)

Equipment Conditions:

Personnel Required:

Radiator auxiliary tank removed from carrier

Metal Worker 44B10

(see your -20)

REPAIR

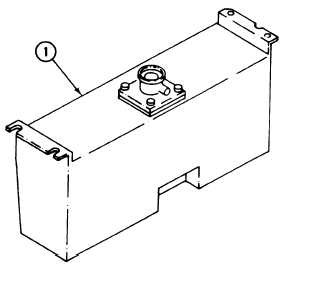

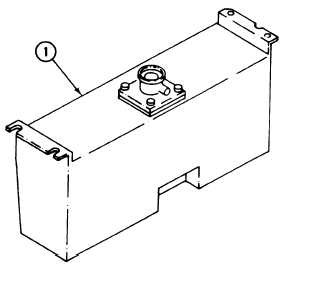

1. Degrease tank ( 1). Use degreaser.

3.

4.

WARNING

Do not exceed 20 psi (137

kPa) pressure while testing

auxiliary tank. Ensure aux-

iliary tank is submerged be-

fore applying air pressure.

Do not direct pressurized

air at yourself or others. Always wear

goggles.

Attach tank (1) to radiator test stand.

NOTE

There are two ways to pressure test tank.

If using water pressure, do step 3, then go

to step 5. If using air pressure, go to

step 4.

Apply internal water pressure of 18–20 psi

for minimum of 3 minutes. Check for water

leaks.

Submerge tank (1) in

3 minutes. Check for

water and apply

for minimum of

air leaks.

NOTE

Mark areas of leaks and remove all plugs

before welding.

5.

6

7.

Weld areas of leaks in accordance with

TM 9–237. Weld all sizes to minimum

requirement for lead repair.

Repeat step 3 or 4 after welding.

Refinish tank

TM 43-0139.

(1) in accordance with

FOLLOW-THROUGH STEPS

1. Install radiator auxiliary tank (see your –20).

END OF TASK

5-5

2.

pressure of 18-20 psi