TM 9-2350-261-20-2

R E P L A C E A U X I L I A R Y T A N K T O C O O L A N T P U M P T U BE

INITIAL SETUP

Tools:

References:

General Mechanic’s Tool Kit (Item 30, App D)

See your -10

Materials/Parts:

Equipment Conditions:

Sealing compound (Item 46, App C)

Engine stopped/shutdown (see your –10)

Carrier blocked (see your -10)

Personnel Required

Trim vane lowered and power plant front

Unit Mechanic

access door open (see your –10)

Drain cooling system (page 8-3)

REMOVE

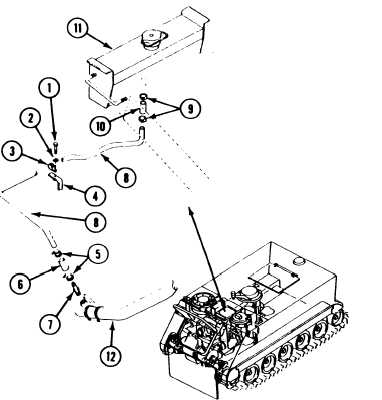

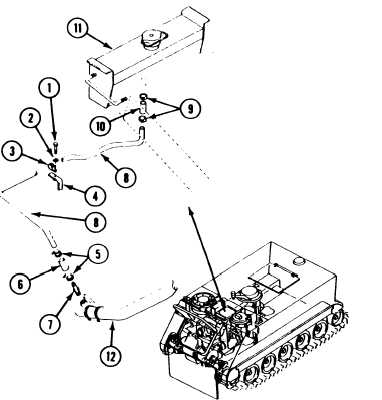

10. Secure hose (6) to tube (8) and adapter (7)

1.

2.

3.

4.

5.

with two clamps (5).

Remove screw (1), washer (2), and clamp (3)

from bracket (4).

11. Secure clamp (3) to bracket (4) with screw

(1) and washer (2).

Loosen two clamps (5). Disconnect hose (6)

from adapter (7) and tube (8).

Loosen two clamps (9). Disconnect hose (10)

from tube (8) and auxiliary tank (11).

Remove adapter (7) from oil cooler

Remove tube (8) from carrier, and

from tube.

INSTALL

6.

7.

8.

9.

eIbow (12).

clamp (3)

Apply a light even coat of sealing compound

to external threads of adapter (7).

Install adapter (7) in oil cooler eIbow (12).

Install clamp (3) on tube (8).

Secure hose (10) to auxiliary tank (11) and

to tube (8) with two clamps (9).

FOLLOW-THROUGH STEPS

1. Fill cooling system (page 8-5).

3. Stop/shutdown engine (see your -10).

2. Start engine (see your –10). Check for leaks.

4. Close power plant front access door and raise

trim vane (see your -10).

END OF TASK

8-30