TM 9-2350-261-20-2

R E P L A C E F A N D R I V E P U L L E Y A N D A C C E S S C O V E R

INITIAL SETUP

Tools:

References:

General Mechanics Tool Kit (Item 30, App D)

see your -10

Torque Wrench Adapter (Item 9, App D)

Torque Wrench (Item 95, App D)

Equipment Conditions:

Materials/Parts:

Engine stopped/shutdown (see your -10)

Carrier blocked (see your -10)

Lockwasher (4)

Power plant rear access panel removed

(page 24-27 or 24-29)

Personnel Required:

Unit Mechanic

R E M O VE

7. Using torque wrench adapter, tighten nut (5)

to 300-360 lb-in (34-41 N•m) torque. Use

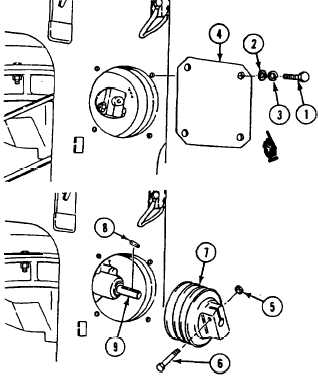

1.

2.

3.

Remove four screws (1), flat washers (2),

lockwashers (3), and fan pulley access

cover (4) from power plant compartment rear

bulkhead. Discard l&washers.

torque wrench.

8. Secure cover (4) to power plant compartment

rear bulkbead with four flat washers (2), new

lockwashers (3), and screws (1).

Remove fan drive belts (page 8-35).

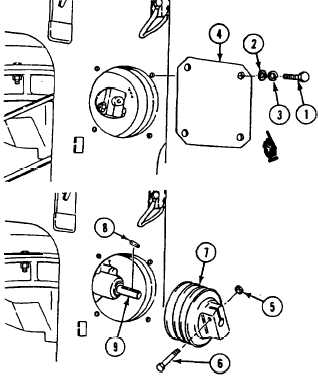

Remove nut (5), screw (6), pulley (7), and

key (8) from shaft (9).

INSTALL

4.

5.

6.

NOTE

-Place pulley (7) on fan shaft (9) with the

bolt and nut facing down as shown. Install

key (8) making sure key is flush with ends

of pulley and fan shaft. This will insure

proper alignment and pulley balance.

Install key (8) and pulley (7) on fan shaft

(9). Secure with screw (6) and nut (5) in

pulley hub. Do not tighten nut (5) at this

time.

Install and adjust fan drive belts

(page 8-35).

Align groove of pulley (7) with grooves of

idler pulley and fan drive pulley.

FOLLOW-THROUGH STEPS

1. Install power plant rear access panel

(page 24-27 or 24-29).

END OF TASK

Change 4

8-41