CLEAN, INSPECT, AND

W A R N I N G

REPLACE

D ry

cleaning

solvent

P-D-680 is toxic and flam-

mable. Always use in an

open area with good air

flow, away from sparks,

heat, or flames. Wear gog-

gles and gloves. Do not breathe vapors.

Avoid contact with skin, eyes, and clothes.

If you get dizzy while using solvent,

breathe fresh air and get medical help. If

solvent gets on hands, wash them. If

solvent gets in eyes, flush eyes with fresh

water and get medical help immediately.

Keep fire extinguisher nearby.

8.

9.

10.

Clean parts with dry cleaning solvent.

Check vent tube, filler tube, and dipstick.

Replace cracked or bent tubes or dipstick.

Check fittings. Replace fittings that are

cracked or have stripped threads.

INSTALL

11.

12.

13.

14.

15.

Apply a light coat of sealing compound to

cleaned threads of fittings before installation.

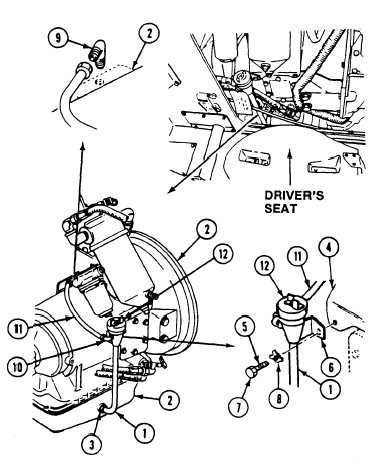

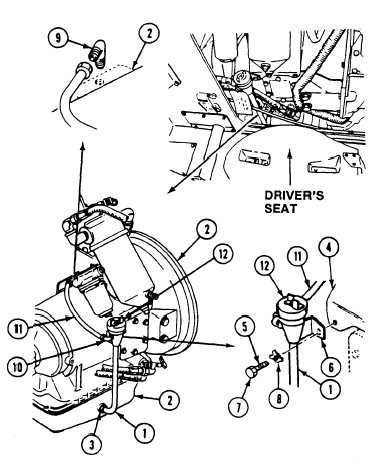

Install filler tube (1) in transmission (2).

Tighten filler tube nut (3) finger tight.

Place filler tube (1) against engine oil filter

bracket (4).

Apply antiseize compound to threads of

16.

17.

18.

19.

20.

21.

TM 9-2350-261-20-2

Install elbow (9) in transmission (2).

Install elbow (10) in filler tube (1).

Connect vent tube (11) in filler tube (1).

Install dipstick (12) in filler tube (1).

Fill transmission with oil (see your LO).

Start engine (see your -10). Check for leaks.

screw (5). Secure filler tube (1) to bracket

(6) with screw (7) and new tab washer (8).

Tighten tube filler nut (3).

FOLLOW-THROUGH STEPS

1. Stop/shutdown engine (see your -10).

4.

2. Install driver’s power plant access panel

(page 24-25).

5.

3. Install air cleaner element and container

6.

(page 7-7)

Close power plant front access door

(see your -10).

Raise trim vane (see your -10).

InstalI hull bottom access cover (page 24-32).

END OF TASK

18-7