TM 9-2350-261-20-2

REPAIR RECEPTACLE

DESCRIPTION

This task covers:

Remove (page 14-7).

Install (page 14-8).

INITIAL SETUP

Tools:

General Mechanics Tool Kit (Item 30, App D)

Soldering Gun (Item 34, App D)

Digital Multimeter (Item 43, App D)

Electrical Tool Kit (Item 75, App D)

Materials/Parts:

Insulation sleeving (Item 21 thru 25, App C)

Solder (Item 57, App C)

REMOVE

CLEAN, INSPECT, AND REPAIR

Personnel Required:

Unit Mechanic

References:

See your -10

See your -24P

Equipment Conditions:

Engine stopped/shutdown (see your -10)

Battery ground lead disconnected (page 13-2)

Carrier blocked (see your -10)

1.

2.

3.

4.

N O T E

5.

Use same procedure for repairing single

or multiple lead, and male or female

receptacle.

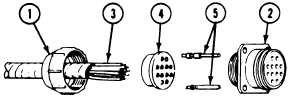

Loosen nut (1) from receptacle (2). Slide nut

back on leads (3).

6.

Remove grommet (4) with contacts (5) from

rear of receptacle (2).

7.

Push leads (3) into grommet (4) until

contacts (5) are fully exposed on other side of

grommet. Remove grommet (4) and nut (1)

from leads (3).

Clip or desolder leads from contacts. Use

soldering gun. Discard contacts.

Check wire leads. Look for damaged

insulation or broken wires. If wire leads have

been taped together, remove tape. Scrape wire

lead covering with your thumbnail to see if

covering peels off. Replace bad leads.

Check contact pins, contact sockets, and

terminals. Replace burned, bent, or broken

parts.

Check shells, sleeves, and nipples. Replace

cut, torn, or damaged parts.

GO TO NEXT PAGE

14-7