TM 9-2350-261-34

R E P A I R F U E L T A N K ( M 5 7 7 A 2 A N D M 1 0 6 8 O N L Y)

I

DESCRIPTION

This task covers:

Clean (page 4-14).

Repair (page 4-15).

INITIAL SETUP

T o o k

Metal Worker’s Tool Kit (Item 61, App B)

Trailer-Mounted Welding Shop

(Item 96, App B)

Materials/Parts:

Sealing compound (Item 73, App C)

wiping rag (Item 86, App C

Personnel Required:

Metal Worker 44B10

References:

See your -10

See your -20

TM 9-237

Equipment Conditions

Fuel tank removed from carrier (see your -20)

Fuel tank access cover removed (see your -20)

Fuel quantity sending unit removed

(see your -20)

C L E A N

1.

W A R N I NG

Fuel fumes can explode and

burn you. Before weding:

Drain all fuel. Disconnect

2.

and cap all fuel and vent

lines. Purge fuel residue

and

f u m e s b y

steam

cleaning. Purge air from fuel tank with

3.

C 0 2.

Use a wire brush to remove paint and dirt

from outer surface area to be welded.

W A R N I N G

Air pressure in excess of 30

psi (207 kpa) can injure per-

sonnel Do not direct pres-

surized air at yourself or

others. Always wear gog-

gles.

C A U T I O N

Do not expose sealed areas to steam for

more than 15 minutes, as existing seal will

begin to deteriorate.

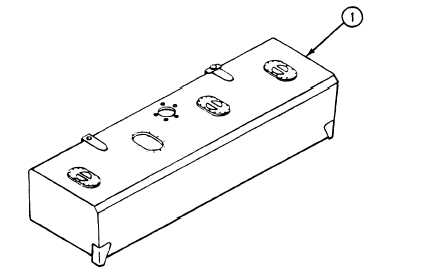

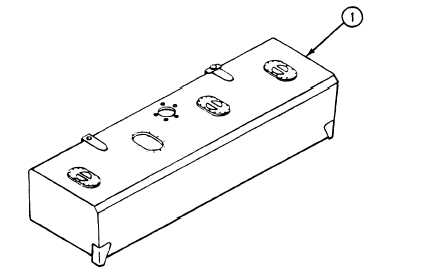

Steam clean inside of fuel tank (1). Use clean

rags and 30 psi (207 kPa) compressed air to

d r y

Direct carbon dioxide or argon gas into fuel

tank (1) at 30-60 cubic feet (0.84-1.68 cubic

meters) per hour until gas escapes from

access cover openings.

4-14

Change 3