TM9-2350-261-20-2

19.

20.

21.

22.

23.

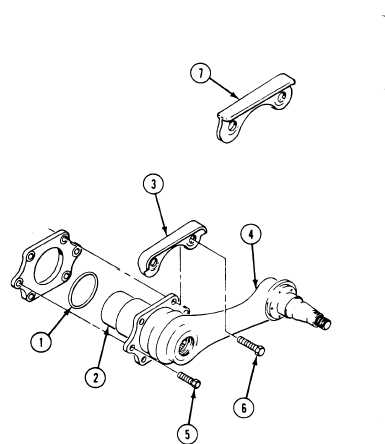

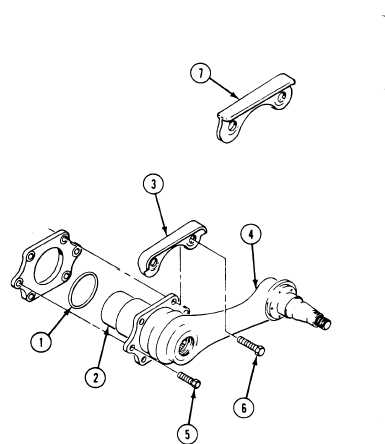

Install new packing (1) on assembly (2).

Secure guard (3), packing (l), and assem-

bled road wheel support arm assembly (4) to

hull (number four and five positions) with

four screws (5) and two screws (6). Tighten

six screws to 130–140 lb-ft (176-190 N•m)

torque. Use torque wrench (Item 96) (All

except M741A1.)

Secure guard (7), packing (1) and assembled

road wheel support arm assembly (4) to hull

(number three position) with four screws (5)

and two screws (6). Tighten SiX screws to

130-140 lb-ft (176–190 N•m) torque. Use

torque wrench (Item 96) (All except

M741A1.)

Secure assembled road wheel support arm

(4) to hull (number one positions) with six

screws (6). Tighten screws to 130-140 lb-ft

(176-190 N•m) torque. Use torque wrench.

(Item 96) All except M741A1.)

Secure assembled road wheel support arm

(4) to hull (number two, three, four, and

five positions) with five screws (5). Use SiX

screws (number one position). Tighten

screws to 130-140 lb-ft (176-190 N•m)

torque. Use torque wrench (Item 96)

(M741A1 only.)

F O L L O W - T H R O U G H S T E PS

1. Install torsion bar (page 22-32).

5.

2. If removed, install shock absorber

6.

(page 22-26).

7.

3. Install road wheel hub (page 22-9).

4. Install road wheel (page 22-7).

8.

Lube road wheel supports (see your LO).

Install track shroud and covers (page 22-2).

Remove blocks used to keep carrier from mov-

ing (see your -10).

Road test carrier (page 2-91) to check that

arm is installed properly.

END OF TASK

22-14

Change 1