TM 9-2350-261-20-2

5.

6.

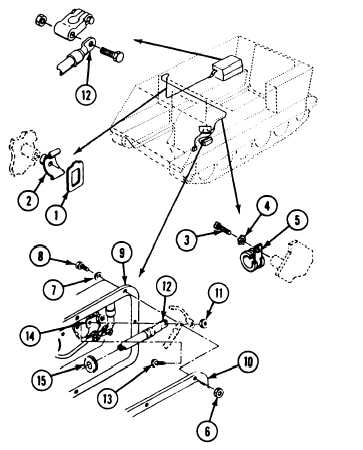

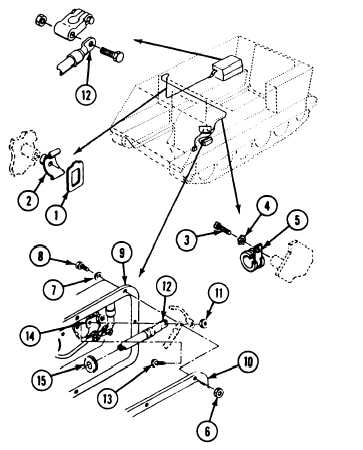

On M106A2 and M125A2 carriers, remove

one clip (1) from cradle (2). Remove two

SCrewS (3), washers (4), and clamps (5)

from two hull weldnuts.

Remove eight nuts (6), washers (7), screws

(8), and master switch panel (9) from

distribution box (10).

NOTE

Nut (11) and screw (13) secure three

leads circuits 2, 6, and 400, to the master

switch bus bar, on all carriers covered by

this task except M741A1. On M741A1

carriers the nut and screw secure two

leads, circuits 6 and 400, to the bus bar.

7.

8.

Remove nut (11), lead (12), and screw (13)

from master switch bus bar (14). Remove

lead and grommet (15) from panel (9).

Discard grommet.

Pull lead (12) from hull support channel. Re-

move lead from carrier. --

WARNING

Battery posts and cables

touched by metal objects

can short circuit and bum

you. Do not wear jewelry,

necklaces, or watches when

working on the electrical

system. Keep tools away from posts,

wires, and terminals.

CAUTION

Do not start vehicles while batteries are

disconnected.

S t a r t i n g e n g i n e w i th

outside power will damage electrical

components in the regulator.

CLEAN, INSPECT, AND REPAIR

9. Clean lead terminals and mating surfaces

with terminal cleaner.

10. Check leads. Replace worn leads and dam-

aged connectors (page 14-3).

INSTALL

11. Route circuit 6 lead (12) through hull sup-

port channel.

12. Install new grommet (15) on lead (12). In-

stall lead and grommet in master switch

panel (9).

NOTE

Nut (11) and screw (13) secure three

leads, circuits 2,6, and 400, to the master

switch bus bar on all earners except

M741A1. On M741Al carrier the nut and

screw secure two leads, 6 and 400. Be sure

you secure all leads to the master switch

bus bar when you install the screw (13)

and nut (11).

13. Place lead (12) on master switch bus bar

(14). Secure with screw (13) and nut (11).

14. Place panel (9) on distribution box (10). Se-

cure with eight washers (7), screws (8), and

nuts (6).

13-14