TRACK ADJUSTER: DISASSEMBLY AND ASSEMBLY

Test Equipment/Special Tools:

Arbor press (item

Vise

Vise jaw caps

Materials/Parts:

1, Appx D)

Automotive grease (item 25, Appx B)

Dry-cleaning solvent (item 17, Appx B)

DISASSEMBLY

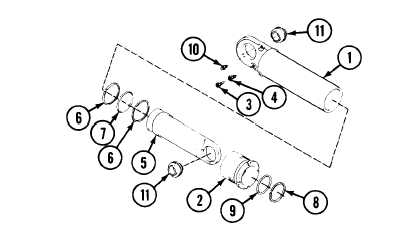

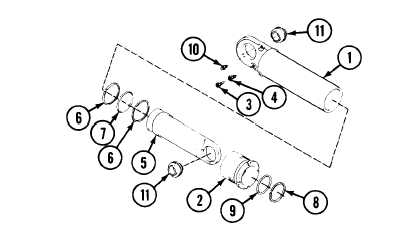

A Place cylinder (1

B Remove nut (2),

cylinder (1).

of track adjuster in vise.

bleeder plug (3) and bleeder body (4) from

C Pull piston (5) from cylinder (1).

D Remove two retainers (6) and packing (7) from piston (5).

Discard retainers and packing.

E

Remove wiper ring (8) and packing (9) from nut (2). Discard

wiper ring and packing.

F

Remove lubricating fitting (10) from cylinder (1).

G Remove cylinder (1) from vise.

H Check two bearings (11) for smoothness of operation, security

of installation or other damage. If bearings (11) are good, go

to step J.

I

Using arbor press (item 1, Appx D), press bearing(s) (11) from

end of cylinder (1) and/or piston (5). Discard bearing(s).

WARNING

Dry-cleaning solvent (PD-680) is toxic and flam-

mable. To prevent personal injury when using

PD-680, use only in a well ventilated area. Avoid

breathing vapors. If you become dizzy get fresh

air immediately and seek medical attention. Avoid

contact with eyes, skin and clothing. Use protec-

ive goggles, gloves, and clothing. If contact is

made, immediately flush with water and seek

medical attention. The flashpoint for Type I dry-

cleaning solvent is 100° F (38 0C); for Type II it is

138 °F (50 °C). Do not use near open flame or ex-

cessive heat.

J

Clean all parts using dry-cleaning solvent (item 17, Appx B).

T A 3 1 2 5 5 0

7-31

Change 1

TM 9-2350-267-34