TM 9-2350-261-34

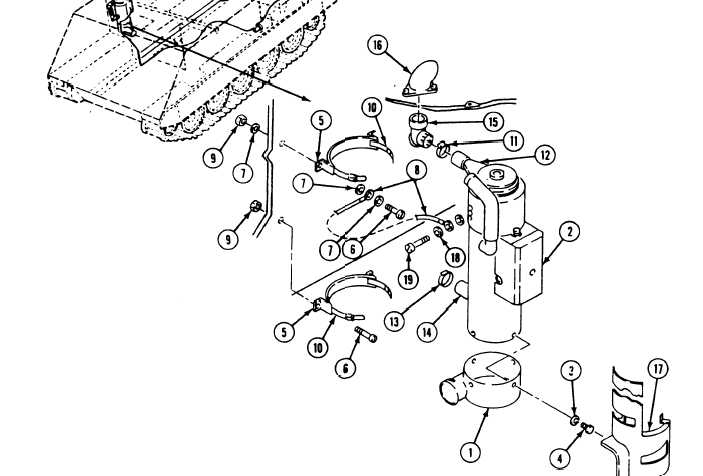

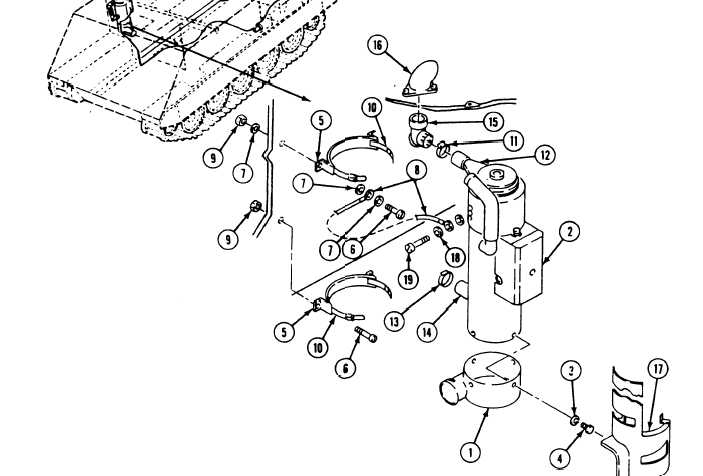

17. Secure plenum (1) to heater (2) with four

lockwashers (3) and screws (4).

N O T E

Four nuts and screws were previously

removed and retained. However, on the

M113A2 carrier, screw that secures strap

is supplied in the personnel heater kit.

18.

19.

20.

Secure two saddles (5) to power plant

bulkhead with four retained screws (6),

three lockwashers (7), ground strap (8) and

four retained nuts (9).

Install two clamps (10) in two saddles (5).

Position clamp (11) on heater intake

pipe (12) and place clamp (13) on heater

exhaust pipe (14). Do not tighten.

22.

23.

24.

25.

26.

Install elbow (15) in heater intake pipe (12)

and intake elbow (16).

Align inlet elbow (15) with intake elbow

(16), and align exhaust pipe (14) with

exhaust pipe in carrier. Place heater (2) and

shield (17) (M113A2 only) against

saddles (5).

While still supporting heater, double check

for proper mating of heater exhaust

port (14) and exhaust pipe in earner.

Tighten two saddle clamps (10).

Position ground strap (8) on heater (2) and

secure with (one M113A2) (two M741A1)

lockwasher(s) (18) and screw (19) (741A1

use existing screw) (M113A2 discard existing

screw and use kit screw).

Tighten clamp (13) on heater exhaust

pipe (14) and exhaust pipe in carrier.

Tighten clamp (11) on heater intake

pipe (12).

11-4

21.