TM 9-2350-261-34

REPAIR/REPLACE ACCELERATOR STOP SUPPORT ASSEMBLY

DESCRIPTION

This task covers:

Remove (page 8-38).

Install (page 8-39).

INITIAL SETUP

Tools:

References:

Metal Worker’s Tool Kit (Item 61, App B)

Adapter (Item 2, App B)

Arc Welding Machine (Item 102, App B)

Electrical Disc Sander (Item 77, App B)

Industrial Goggles (Item 37, App B)

Trailer Mounted Welding Shop

(Item 96, App B)

Welder’s Gloves (Item 36, App B)

Welder’s Helmet (Item 42, App B)

Materials/Parts:

Rivets

Support assembly

Welding electrode (Item 83, App C)

See your -10

See your –20

TM 9-237

Equipment Conditions:

Engine stopped/shutdown (see your –10)

Carrier blocked (see your –10)

Ramp lowered (see your –10)

Driver’s seat removed (see your –20)

Upper accelerator pedal removed

(see your –20)

Lower accelerator pedal removed

(see your –20)

Battery ground disconnected (see your -20)

Personnel Required:

Metal Worker 44B10

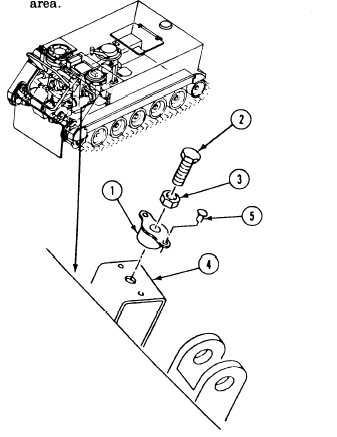

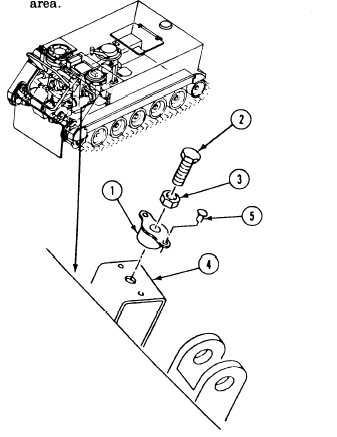

REMOVE

NOTE

To replace nut (1) only, go directly to

step 2.

1.

2.

3.

Remove screw (2) and nut (3) from support

assembly (4).

Use a machinists hammer and a cold chisel

to remove two rivets (5) securing nut (1) to

support. Remove nut.

Remove broken support assembly (4) from

floor plate. Discard ‘broken support assembly.

WARNING

Metal chips and grinding

dust can cause eye injury.

Wear goggles and gloves.

4. Use a machinist’s hammer and a cold chisel

to chip off remaining part of bad support as-

sembly from floor plate.

5. Use a disc sander to sand chipped area

smooth and remove hard coating from weld

8-38