TM 9-2350-261-20-2

R E P L A C E D I F F E R E N T I A L S T E E R I N G B R A K E L E V E R S

I N I T I A L S E T U P

Tools:

References:

General Mechanics Tool Kit (Item 30, App D)

See your -10

Torque Wrench (Item 95, App D)

Equipment Conditions:

Materials/Parts:

Engine stopped/shutdown (see your -10)

Self-locking nut (2)

Carrier blocked (see your -10)

Trim vane lowered and power plant front

Personnel Required:

access door open (see your -10)

Unit Mechanic

REMOVE

INSTALL

1.

2.

3.

Disconnect two return springs (page 23-2).

6.

Disconnect two differential links (page 23-19).

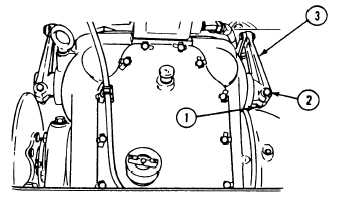

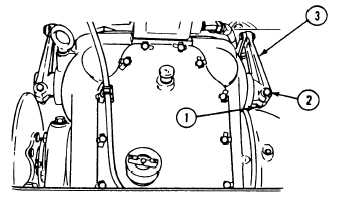

Remove two locknuts (1), screws (2), and two

7.

brake levers (3) from differential brake lever

shafts. Discard locknuts.

C L E A N , I N S P E C T , A N D R E P A IR

4.

5.

Check levers. Replace

worn clevis pin holes.

Check levers. Replace

chipped splines.

9.

levers with cracked or

10.

levers with damaged or

Install two levers (3) on differential brake

lever shafts. Secure with two screws (2) and

new locknuts (1).

Tighten nuts (1) to 360-420 lb-in torque.

Use torque wrench.

Connect two differential links (page 23-19).

Adjust linkage (page 23-2).

Connect two return springs (page 23-2).

FOLLOW-THROUGH STEPS

1. Close power plant front access door and raise

2. Operate steering levers to check that

trim vane (see your –10).

differential steering brake levers operate

properly.

23-20

END OF TASK

8.