TM9-2350-261-20-2

R E P L A C E D I F F E R E N T I A L G E A R B O X T O D I F F E R E N T I A L H O S E

A N D F I T T I N G S

D E S C R I P T I O N

This task covers:

Remove (page 21-12)0

Clean, Inspect and Replace (page 21-12).

Install (page 21-13)

I N I T I A L S E T U P

Tools

General Mechanics Tool Kit (Item 30, App D)

Torque Wrench (Item 95, App D)

Materials/Part:

Antiseize compound (Item 4, App C)

Sealing compound (Item 51, App C)

Self-locking nut

Personnel Required:

Unit Mechanic

References:

See your -10

See your LO

Equipment Conditions:

Engine stopped (see your -10)

Carrier blocked (see your -10)

Trim vane lowered (see your -10)

Power plant front access door open

(see your -10)

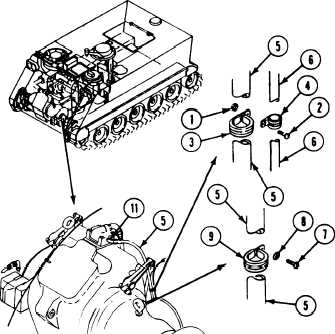

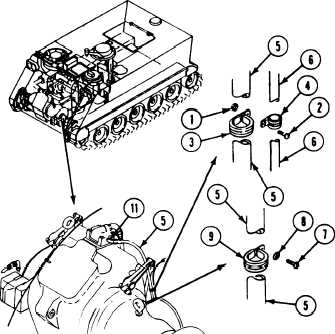

R E M O V E

1.

2.

3.

4.

5.

Remove locknut (1), screw (2), and two

clamps (3 and 4). Separate differential oil

hose (5) from circuit 328 lead (6). Discard

locknut.

Remove screw (7), washer (8), clamp (9), and

oil hose (5) from differential (10).

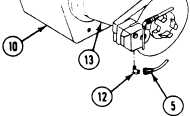

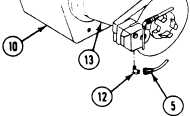

Disconnect oil

(11 and 12).

Remove elbow

Remove elbow

“’ hose (5) from two elbows

(11) from differential (10).

(12) from differential

gearbox (13).

C L E A N , I N S P E C T A N D R E P L A CE

6. Check fittings, hardware, hoses and differen-

tial housing for leaks, cracks, wear and dam-

age. Replace as needed.

21-12