TM9-2350-261-20-2

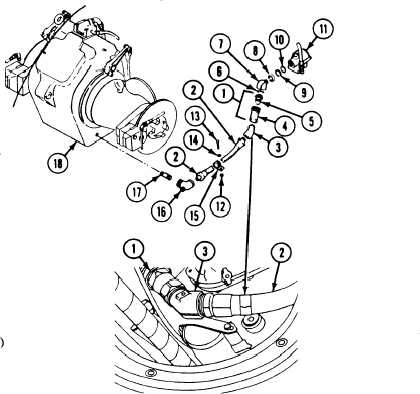

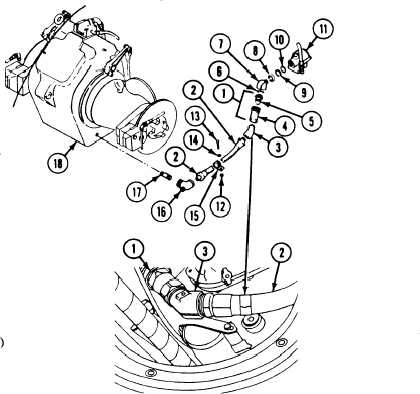

R E P L A C E D I F F E R E N T I A L O I L P U M P T O D I F F E R E N T I A L H O S E

A N D F I T T I N G S

D E S C R I P T I O N

This task covers:

Remove (page 21-11).

Clean, Inspect, and Replace (page 21-12)

Install (page 21-12).

I N I T I A L S E T U P

Tools:

General Mechanics Tool Kit (Item 30, App D)

Pipe wrench (item 86, App D)

Suitable container

Materials/Parts:

Sealing compound (Item 59, App C)

Preformed packing

Self-locking nut

Personnel Required:

Unit Mechanic

References:

See your -10

See your LO

Equipment Conditions:

Engine stopped/shutdown (see your -10)

Carrier blocked (see your -10)

Trim vane lowered (see your -10)

Power plant front access door open

(see your -10)

Hull bottom access cover removed

(page 24-32)

R E M O V E

1.

2.

3.

4.

5.

6.

7.

8.

Drain differential oil into suitable container

(see your LO).

Remove differential high oil temperature

switch(page15-4).

Disconnect differential oil hose quick

disconnect coupling (1).

Disconnect differential oil hose (2) from

elbow (3).

Remove elbow (3) from quick disconnect cou-

pling half (4).

Remove quick disconnect coupling half (5)

and preformed packing (6) from elbow (7).

Discard packing.

9. Disconnect hose (2) from tee (16).

10. Remove tee (16) from bushing (17).

11. Remove bushing (17) from differential

Remove elbow (7), nut (8), retainer (9), and

preformed packing (10) from differential oil

pump (11). Discard packing.

Remove locknut (12), screw (13), washer

(14), clamp (15), and differential oil hose (2)

from hull crossbeam. Discard locknut.

(18).

21-10