C L E A N , I N S P E C T , A N D R E P L A C E

12. Check fittings, hardware, hoses and pump

housing for leaks, cracks, damage and wear.

Replace as needed.

I N S T A L L

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

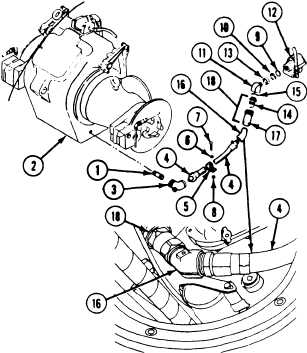

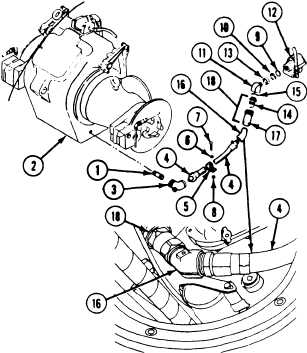

Apply a thin even coat of sealing compound

to cleaned threads of fittings before

installation.

Install bushing (1) in differential (2).

Install tee (3) on bushing (1).

Connect differential oil hose (4) to tee (3).

Secure hose (4) to hull crossbeam with

clamp (5), washer (6), screw (7), and

new locknut (8).

Install new preformed packing (9), retainer

(10), and elbow (11), in differential oil pump

(12). Secure with nut (13).

Install quick disconnect half (14) and new

packing (15) in elbow (11).

Install elbow (16) in quick disconnect

half (17).

Connect hose (4) to elbow (16).

Connect oil hose quick disconnect

coupling (18).

23. Install

switch

TM9-2350-261-20-2

differential high oil temperature

(page 15-4).

24. Fill differential with oil (see your LO).

W A R N I NG

25. Start engine

leaks.

Loose clothing is dangerous

around moving belts and

pulleys. You could get bad-

ly hurt if your clothes get

caught in moving parts.

(see your -10). Check for oil

F O L L O W - T H R O U G H S T E P S

1. Engine stopped/shutdown (see your -10).

3. Close power plant front access door

(see your -10).

2. Install hull bottom access cover (page 24-32).

4. Raise trim vane (see your -10).

END OF TASK

21-11