TM 9-2350-261-34

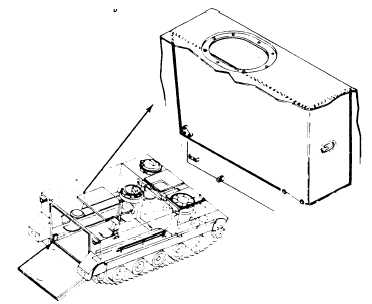

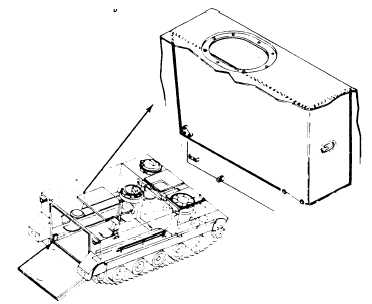

R E S E A L F U E L C O M P A R T M E N T W E L D J O I N T S ( M 1 2 5 A 2 , M 1 0 6 A 2 ,

A N D M 7 4 1 A 1 O N L Y)

DESCRIPTION

This task covers:

Clean (page 4-6),

Reseal (page 4–7).

I N I T I A L S E T U P

Tools:

General Mechanics Tool Kit (Item 35, App B)

Electrical Gun Type Heater (Item 41, App B)

Materials/Parts:

Wiping rags (Item 86, App C)

Fuel tank repair kit 2540-00-133-9593

Personnel Required:

Track Vehicle Repairer 63H10

References:

See your –10

see your -20

Equipment Conditions:

Ramp lowered (see your -10)

Engine stopped (see your –10)

Carrier blocked (see your –10)

Fuel compartment drained (see your–20)

Fuel filler assembly removed (see your-20)

Left taillight, leads, and guards removed

(see your -20)

Left taillight wiring harness and guard

removed (see your –20).

Fuel quantity sending unit removed

(see your –20)

Fuel supply and return hoses and fittings

removed (see your –20 )

Rear main wiring harness and guard removed

(see your –20)

C L E A N

W A R N I N G

1.

2.

and cap all fuel and vent

Fuel fumes can explode and

burn you. Before welding

Drain all fuel. Disconnect

L

J

and

f u m e s b y

steam

cleaning. Purge air from fuel tank with

C02.

Use a wire brush to lightly buff existing

sealing compound on weld joints on inside of

fuel compartment.

Buff an area 1–1/2 inches (4cm) wide on

both sides of weld joint centerline that is to

be resealed on outside of fuel tank.

W A R N I NG

Air pressure in excess of 30

psi (207 kPa) can injure

personnel.

Do not direct

pressurized

or others.

goggles.

air at yourself

Always wear

3.

4.

C A U T I O N

Do not expose sealed areas to steam for

more than 15 minutes because existing

seal will begin to deteriorate.

Steam clean inner and outer surfaces of fuel

compartment.

Rinse fuel compartment with hot water. Use

clean rags and 30 psi (207 kPa) compressed

air to dry.

4-6

lines. purge fuel residue