TM 9-2350-261-34

R E P A I R

W A R N I N G

Fuel fumes can explode and

bum you. Before welding:

Drain all fuel. Disconnect

and cap all fuel and vent

lines. Purge fuel residue

and

fumes

b y

steam

cleaning. Purge air from fuel tank with

C02.

N O T E

Repair entire weld joint all around the

fuel compartment.

5.

6.

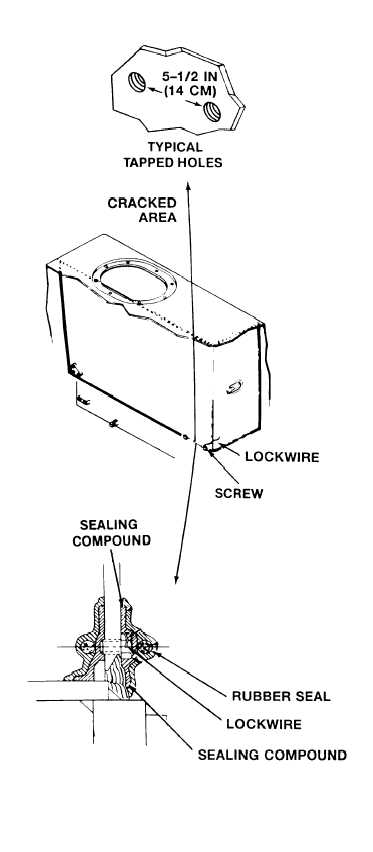

Drill and tap eight 3/8 x 16 UNC-2A (10

mm) deep holes on centerline of weld joint

crack about 5–1/2 inches (14 cm ) apart,

regardless of crack length.

Install eight 3/8 x 16 UNC2A (10 mm)

screws in tapped holes. Tighten screws to

144-180 in-lb (16-20 N.m) torque. Use

torque wrench. Secure with lockwire.

C A U T I O N

Do not apply sealing compound in

temperatures under 45°F (7°C). Com-

pound will not set at low temperature.

7.

8.

9.

10.

11.

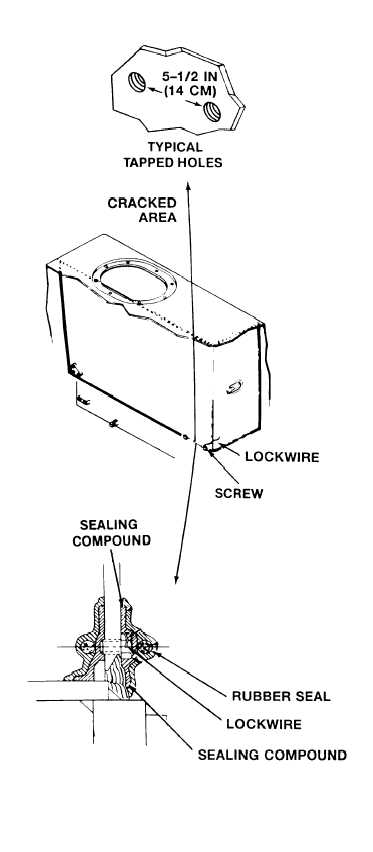

Apply one layer of sealing compound

1/8-1/4 inch (3-6 mm) thick. Extend seal

about 1 inch (3 cm) on both sides of weld

joint centerline and over screw threads.

While sealing compound is still tacky, lay a

new rubber seal over centerline of inside and

outside of fuel compartment weld joints.

Allow first layer of sealing compound to set

for at least 4

layer.

Apply second

1/8-1/2 inch

1/4–1/2 inch

first layer of

Allow second

set 40 hours

used and 48

hours before applying second

layer of sealing compound

(3-13 mm) thick. Extend seal

(6-13 mm) behind edges of

sealing compound.

layer of sealing compound to

at 72°F (22°C) if class B2 is

hours if class B4 is used.

N O T E

To speed sealant setting

electrical gun type heater.

200°F (93°C).

time, use an

Do not exceed

4-4