TM 9-2350-261-20-1

2 0 0 A M P F U L L F I E L D C H A R G E T R O U B L E S H O O T I N G

INITIAL SETUP

Tools:

General Mechanic’s Tool Kit (Item 30, App D)

Multimeter (Item 43, App D)

Electrical Connector Pliers (Item 44, App D)

Alternator Test Kit (Item 74.1, App D)

Personnel Required:

Unit Mechanic

References:

See your -10

Equipment Conditions:

Engine stopped (see your -10)

Carrier blocked (see your -10)

Ramp lowered (see your -10)

All radios and heaters OFF (see your -10)

Battery box cover removed (page 13-3) or

battery drawer open (page 13-24)

1. Disconnect batteries (page 13-2).

NO

2. Check all electrical connectors. harnesses. and cannon

plugs before connecting alternator test kit.

3. Are connectors and cannon plugs tight and pins in place

in harnesses?

I

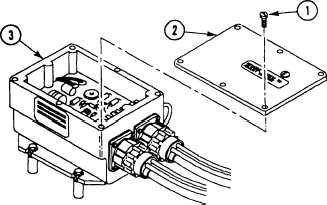

1. Remove six screws (1) and cover (2) from voltage

regulator (3).

2. Connect multimeter to clean unpainted surface and

vehicle ground.

3. Does multimeter read 0.5 ohms or less?

1. Tighten or repair connec-

tions, cannon plugs, and

harnesses. Use electrical

connector pliers.

2. Repeat charging system

operational check

(page 3-64.4).

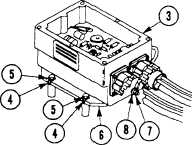

1. Ensure lock washers (4) and

screws (5) are tight on

plate (6).

2. Tighten nut (7) securing

ground lead (8) to

regulator (3).

3. Install cover and screws on

voltage regulator.

4. Repeat charging system

operational check

(page 3-64.4).

G O T O N E X T P A GE

Change 1

3-64.9