TM 92350-287-20-1

I

2-19. TROUBLESHOOTING CHART (continued).

Iw. CREW AFES (continued).

(3) FIRE EXT. LED’S ARE LIT. FAULT LAMP REMAINS

ON.

Initial Setup:

Tools/Test Equipment:

Equipment Conditions:

• Digital multimeter (DMM) (Item 13, Appendix 1)

• Left and right projectile rack assemblies moved

• General mechanic’s tool kit (Item 24,

to rear of vehicle (refer to TM 9-2350-287-10).

Appendix 1)

(for crew extinguishers 1 and 2 only).

• Crew AFES test./alarm panel MAINT switch in

Materials/Parts:

maintenance position (para 21-3).

l Cleaning compound (Item 19, Appendix D)

• Sealing compound (Item 58, Appendix D)

NOTE

l Instead of using

multimete

for voltage

check, STE/lCE

troubleshooting,

INDIVIDUAL

BATTERY VOLTAGE TEST-TEST

89 maybe performed.

• Instead of using multi meter

for continuity check, STE/lCE

troubleshooting, TEST 91 may

be performed.

A. 1. Inspect all six electrical connectors for mois-

ture, contamination, or loose fit.

I

IAre all connections clean, dry, and secure?

I

I

Clean connectors with cleaning compound

and apply sealing compound to connectors

and reinstall. Very promblen is solved.

m

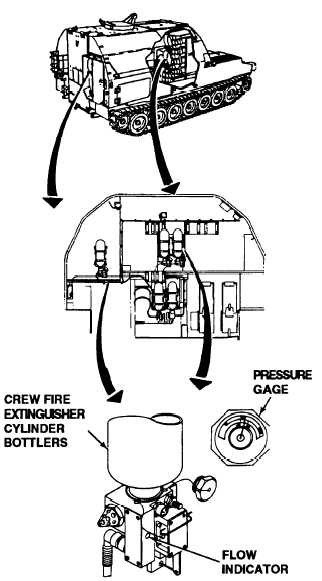

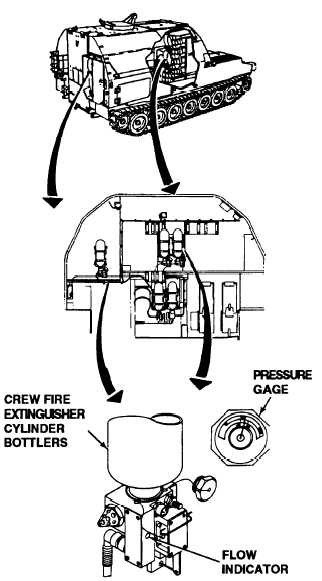

B. 1. Check for protruding flow indicator of

valve actuators of crew fire extinguisher

cylinder bottles 1 thru 6 as indicated by

LEDs on crew T/A paneI.

2. Check pressure gage of crew fire extin-

guishers. Black needle of pressure gage

should be inside green temperature

wedge.

Is pressure gage needle in the correct position,

and flow indicators are not protruding from their

valves?

Continued on next page

2-353