2-19. TROUBLESHOOTING CHART (continued).

g. GAGES (continued).

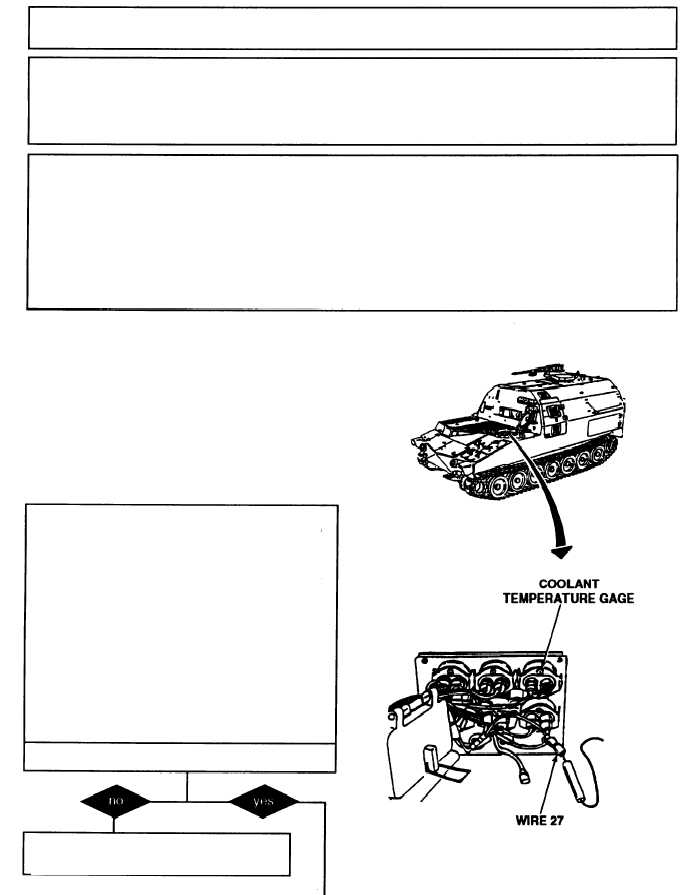

(2) ENGINE COOLANT TEMPERATURE GAGE FAILS

TO OPERATE PROPERLY, NEEDLE DOES NOT

MOVE, IS STEADY, OR INACCURATE. All other

gages operate properly.

Initial Setup:

Tools/Test Equipment:

Equipment Conditions:

• Digital multimeter (DMM) (Item 13, Appendix 1)

• MASTER switch set to OFF (refer to

• General mechanic’s tool kit (Item 24,

TM 9-2350-287-10).

Appendix 1)

• Remove cover from driver’s portable

instrument panel (para 7-6).

Materials/Parts:

• Wire (Item 77, Appendix D)

NOTE

• Instead of using multi meter

for voltage

check, STE/lCE

troubleshooting,

INDIVIDUAL

BATTERY VOLTAGE TEST-TEST

89 maybe performed.

• Instead of using multi meter

for continuity check, STE/lCE

troubleshooting, TEST 91 may

be performed.

A. 1. Disconnect wire 27 from coolant tempera-

ture gage.

2. Place multimeter red lead in wire 27 con-

nector, and ground black lead.

3. Turn MASTER switch ON (refer to TM 9-

2350-287-1 O).

4. Check for 24 ± 3 vdc.

5. Turn MASTER switch OFF (refer to TM 9-

2350-287-10).

Is voltage indicated?

Repair wire 27 or replace harness 12260298

(para 7-7). Verify problem is solved.

Continued on next page

2-103

TM 9-2350-287-20-1