TM 9-2350-277-20-4

REPAIR HULL BY WELDING — Continued

0529 00

7.

When welding unequal sections, direct arc against heavier piece to fuse the two edges evenly. Watch weld pool edge

rather than arc to make sure weld pool edges fuse right.

8.

When performing multi-pass welding, make sure edges of weld pool fuse right. Watch weld pool rather than arc. Any

oscillating or weaving motion should be slight, smooth, and slow. Brush material with clean, stainless steel wire brush

after each pass. On small weldments, lower amperage slightly after each pass if welding members become too hot.

9.

Clean up weld area and touch-up paint all bare metal (see TM 43-0139).

10. Install any parts removed for access.

MIG WELDING METHOD

1.

MIG (Gas Metal Arc Welding) uses a dc power source, control panel, and welding gun. The gun feeds a consumable

bare electrode at a given rate into a molten pool beneath a blanket of inert gas. When an arc is struck, a molten pool

forms at once. Move the welding gun along the joint line at a rate that shapes the right size bead. The covering of inert

gas keeps air from polluting the weld zone. No flux is needed.

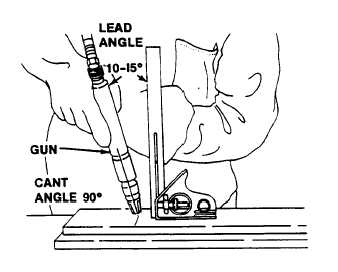

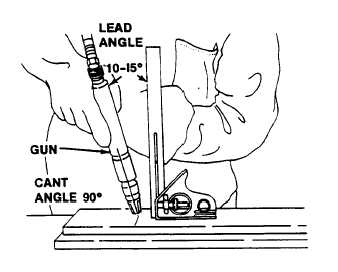

2.

Lead angle and cant angle are important. Place gun at a lead angle of 10

to 15

off vertical. Point gun in direction of

weld travel for good gas coverage, cleaning, and preheating of material. Place gun at cant angle of 90

to parent metal so

filler wire and arc are directed toward apex of groove. This will give equal fusion to both sides of material, even weld

buildup, and equal penetration.

0529 00-5