7-12

Change 4

TM 9-2350-267-34

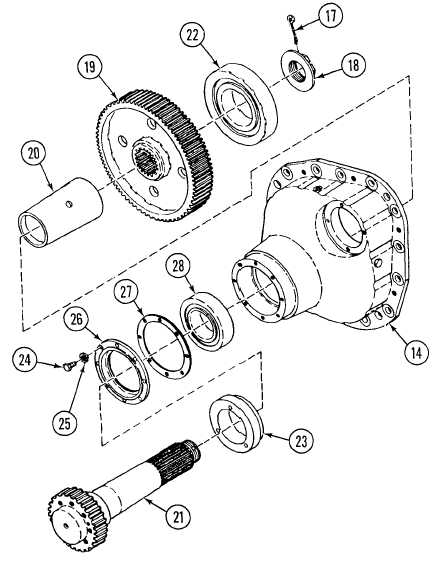

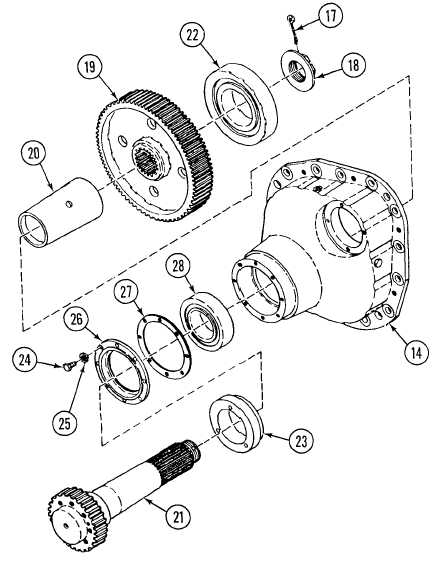

FINAL DRIVE ASSEMBLY REPAIR (CONTINUED)

ASSEMBLY

A

B

C

D

E

F

G

Install bearing (28), new gasket (27) and cap (26) in final drive

housing (14).

Secure with eight new lockwashers (25) and eight screws (24).

Torque screws (24) to 35-40 lb-ft.

Install new seal (23) on output shaft (21). Insert output shaft

(21) into final drive housing (14).

Install bearing (22) on ring gear (19).

Stack spacer (20) and ring gear (19) on output shaft (21).

Apply lubricating oil (item 32, Appx B) to threads of nut (18)

and output shaft (21). Torque nut (18) to 450 to 475 lb ft to

make sure bearing (22), spacer (20) and ring gear

thoroughly seated on output shaft (21).

NOTE

Bend long leg of cotter pin on to flat of nut.

19) are all

Bend

short leg only so far as to not protrude beyond

end of output shaft.

If slot in nut (18) alines with hole in output shaft (21), insert

new cotter pin (17). If slot in nut (18) does not aline with hole

in output shaft (21), torque nut up to 30 lb ft more until a slot in

nut (18) alines with hole in output shaft (21). Insert new cotter

pin (17).