TM 9-2350-261-34

R E P A I R C O M M A N DE R ’ S C U P O L A ( M 1 1 3 A 2 , M 1 0 6 A 2 , M 1 0 6 4 ,

M 1 2 5 A 2 , A N D M 1 0 6 9 O N L Y)

INITIAL SETUP

Tools:

Personnel Required:

General Mechanics Tool Kit (Item 35, App B)

Torque Wrench, 1/2 inch drive

Track Vehicle Repairer 63H10

(Item 114, App B)

Helper (H)

Materials/Parts:

Equipment Conditions:

Lockwasher (18)

Commander’s cupola removed (page 8-2)

R E M O VE

CAUTION

WARNING

Lifting or moving objects in

excess of 70 pounds could

injure you. Get an assistant

or a lifting device to help

move armor or other heavy

objects.

Improper installation will cause binding

resulting in bearing failure. Block (6)

radius surface must face toward cupola

center. Do not use talcum or other pow-

der residue to reduce friction. When ex-

posed to moisture a chalky substance is

formed causing binding.

NOTE

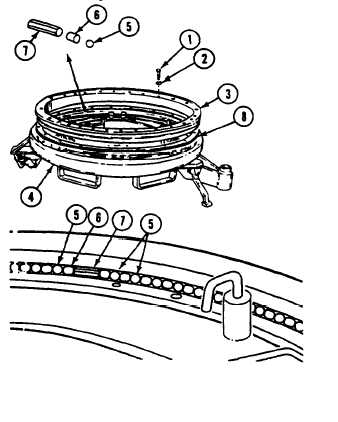

1. Turn cupola over. Remove 18 socket head

screws (1), lockwashers (2), and outer

race (3) from hatch (4). Discard lockwashers.

Have helper assist.

NOTE

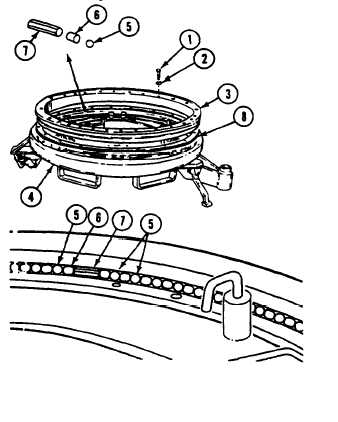

Separators are like bearings except for

size and color. Ball bearings are slightly

larger than separators and are white or

cream color. Separators may be any dark

color.

Alternately, install 24 separators (6) and

23 ball bearings (5) between bearing

blocks (7). One separator (6) is to be

installed on each side of each bearing

block (7). A maximum number of sets (one

ball and one spacer per set) is needed

between any two blocks. The number of

sets in each space between blocks must

not differ by more than one set.

2. Remove 140 ball bearings (5), 146 separators

(6), and 6 bearing blocks (7) from inner race

(8). Remove inner race from hatch (4).

INSTALL

NOTE

lf one ball bearing or separator needs to

be replaced, all ball bearings and separa-

tors must be replaced.

3. Install inner race (8) on hatch (4).

4. Install 140 ball bearings (5), 146 separators

(6), and 6 bearing blocks (7) in groove of

inner race (8).

8-4

Change 4