TM 9-2350-261-20-2

CLEAN, INSPECT, AND REPAIR

6.

7.

8.

9.

Inspect resilient mounts, bumpers, and

grommets for cuts, cracks, tears, and loss of

resilience. If parts are hard, brittle, cut

cracked, or torn, install new parts.

Clean battery box with brush dipped in mix-

ture of sodium bicarbonate. After foaming

stops, flush with clean water and dry with

clean cloth.

Inspect battery box for dents and cracks. If

damaged beyond repair, notify direct support

maintenance.

Inspect frame and divider channel for dents

and cracks. If damaged beyond repair, in-

stall new part.

INSTALL

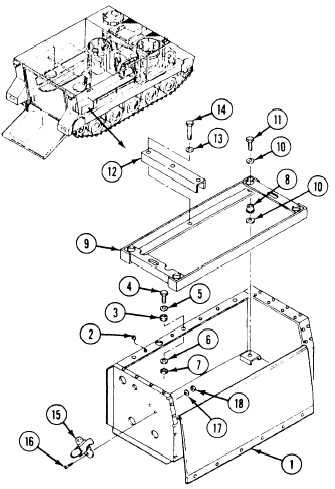

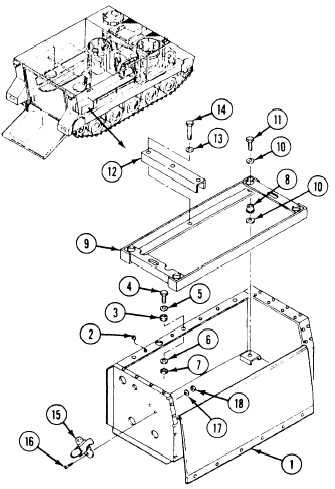

10. Apply epoxy coating to battery box (1).

11. If removed, install battery box cover rubber

bumpers (2) on battery box (1).

12. Install three grommets (3) on battery box

(1). Secure with three screws (4), washers

(5), washers (6), and new locknuts (7).

13. Install four resilient mounts (8) in frame

(9). Place frame in battery box (1) and se-

cure with eight washers (10) and four

screws (11). Tighten screws to 120–192 lb-in

( 113–22 N•m) torque. use torque wrench

and socket.

14.

15.

Place channel divider (12) in battery frame

(9). Secure with two washers (13) and

screws (14). Tighten screws to 84–120 lb-in

( 11–14 N•m) torque. Use torque wrench and

socket.

Place two latches (15) on side of battery box

(1). Secure with four screws ( 16), washers

(17), and new locknuts (18).

FOLLOW-THROUGH STEPS

1. Install batteries and retainers (page 13-16).

3. Start engine. Raise and lock ramp

(see your –10).

2. Install battery leads and box covers

(page 13-3).

4. Stop/shutdown engine ( see your –10 ).

END OF TASK

13-23