TM 9-2350-247-20-2

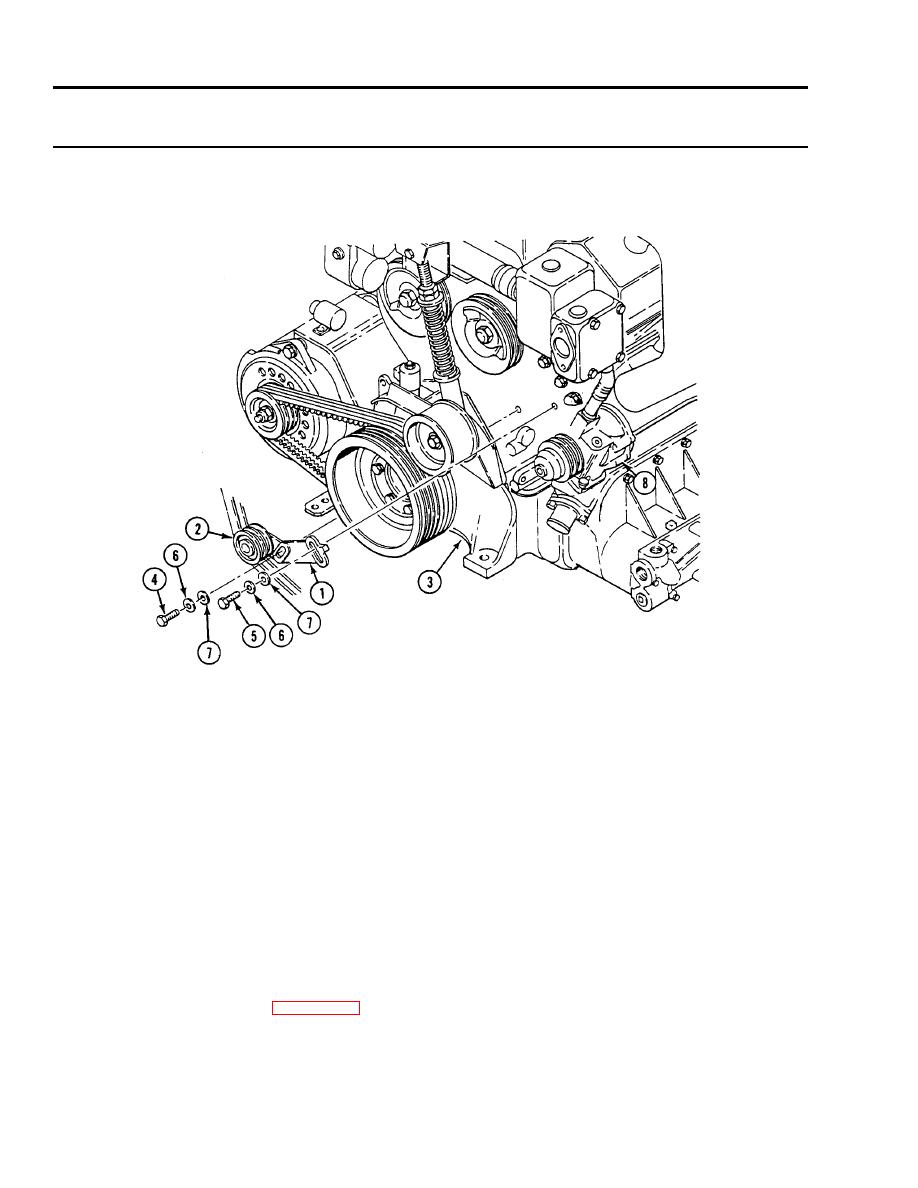

REPLACE COOLANT PUMP IDLER PULLEY AND ADJUSTING BRACKET (M548A3) --

0225 00

Continued

ADJUSTMENT

1.

Loosen cap screw (5) on adjusting bracket (1).

NOTE

Belts should be neither too loose nor too tight. Belts which are too tight impose excess loads on

bearings, shortening life of bearing and belt. Loose belts may slip, causing overheating. Be sure

idler pulley pivot and adjusting bolts are torqued to 30-35 lb-ft (40.7-47.5 Nm).

2.

Loosen adjusting cap screw (5) on bracket slot. Adjust the belt tension so that a firm push with the thumb, at a midway

point between the two pulleys, will depress the belt 1/2-3/4 inch (1.3-1.9 cm). If belt tension gauge J23600-B or

equivalent is available, adjust the belt tension to 40-50 lb (18.2-22.7 kg) on the gauge. New drive belts stretch during the

first few hours of operation. Run the engine 15 seconds to seat the belts, then readjust the tension. Check the belts and

tighten them again in approximately 1/2 hour of operation and again after 8 additional hours of operation. Check the belt

tension every 200 hours and adjust as necessary.

3.

Tighten cap screw (4) and cap screw (5) to 30-35 lb-ft (40.7-47.5 Nm).

FOLLOW-THROUGH STEPS

1.

Install coolant pump drive belts (WP 0224 00).

2.

Install power plant rear access panel (see your -10)

END OF TASK