TM 9-2350-247-20-2

ENGINE FUEL PUMP FLOW TEST

THIS WORK PACKAGE COVERS:

Testing (page 0147 00-1).

INITIAL SETUP:

Maintenance Level

References

Unit

See your -10

Tools and Special Tools

General Mechanic's Tool Kit (WP 0541 00, Item 57)

Equipment Condition

Materials/Parts

Engine stopped (see your -10)

Suitable container

Carrier blocked (see your -10)

Personnel Required

Unit Mechanic

Power plant rear access door/panel removed

Helper (H)

(see your -10)

TESTING

FLOW TEST

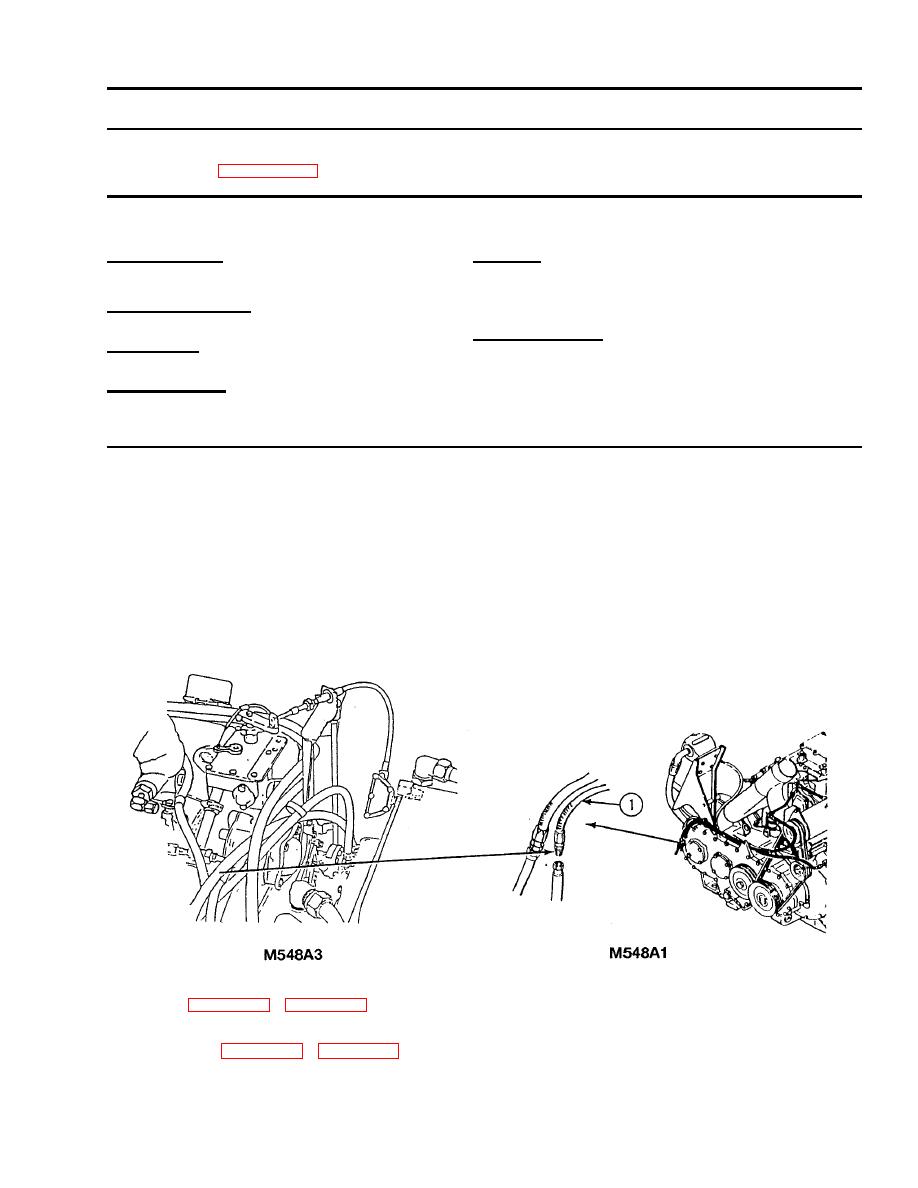

1.

Disconnect fuel return hose (1) and hold over suitable container.

2.

(H) Start engine (see your -10). Run engine at 1200 rpm.

3.

Measure fuel return flow for one minute. Fuel return flow should be about 1/2 gallon per minute (2 lpm).

4.

Put end of fuel return hose (1) into container of fuel. If air bubbles appear on the surface, there is an air leak on the

suction side of the engine fuel pump. Tighten fuel hose connections.

5.

If no air bubbles rise to the surface and fuel flow is not enough for good engine operation, replace primary fuel filter

element (WP 0178 00 or WP 0179 00).

6.

Measure fuel flow, see Step 2 and Step 3. If fuel flow is not enough for good engine operation, replace secondary fuel

filter element (WP 0178 00 or WP 0179 00).

7.

Measure fuel flow, see Step 3.