|

| |

TM 9-2350-287-20-2

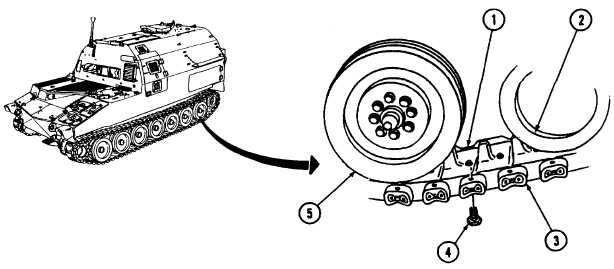

11-13. TRACK SHOE REPLACEMENT.

This Task Covers:

a. Removal

b. Installation

Initial Setup:

Tools/Test Equipment:

Track end connector puller (2) (Item 72,

Crowbar (Item 12, Appendix I)

Appendix I)

General mechanic's tool kit

(Item 24, Appendix I)

Materials/Parts:

Socket wrench socket, 1 1/8-inch, 3/4-inch

Track end connector kit (Item 376, Appendix H)

drive (Item 60, Appendix I)

Socket wrench handle, 3/4-inch drive

Personnel Required: Two

(Item 61, Appendix I)

Socket wrench socket, 1 1/2-inch, 3/4-inch

Equipment Conditions:

drive (Item 62, Appendix I)

Vehicle parked on level ground

Torque wrench, 0-600 ft-lb

(refer to TM 9-2350-287-10).

(Item 70, Appendix I)

Track connecting fixture (2)

(Item 71, Appendix I)

a.

REMOVAL

NOTE

Locking hardware is designed for one-time use only. All self-locking fasteners

must be replaced upon removal.

1.

Move vehicle so track shoe (1) to be removed is midway between roadwheel (5) and idler wheel (2).

2.

Shut off vehicle engine (refer to TM 9-2350-287-10), and block track with chock blocks. Do not set parking brake.

3.

Decrease track tension (refer to TM 9-2350-287-10).

4.

Remove four bolts (4) from four end connectors (3) on track shoe (1). Discard bolts.

Change 1 11-28

|