TM 9-2350-287-10

Table 2-1. Preventive Maintenance Checks and Services for Model M992A1

Location

Item Interval

Crewmember

Not Fully Mission

No.

Item to

Procedure

Capable If:

Check/

Service

24 During

Conveyor

(continued)

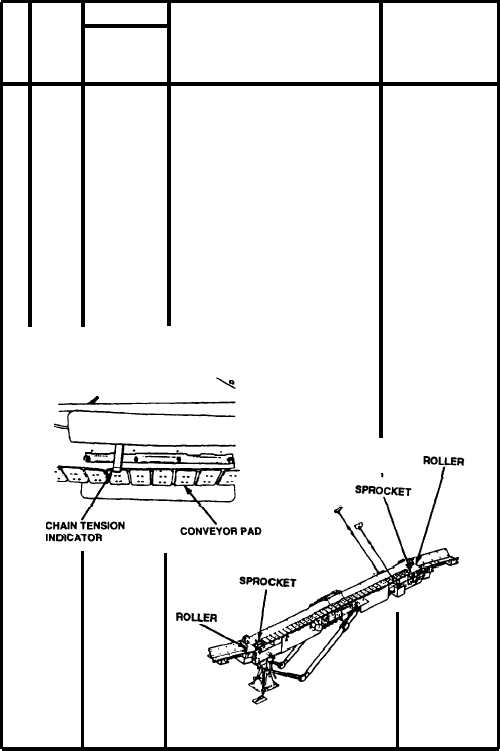

b. Check conveyor chain tension

(p. 3-43). Tension is correct when tops

of plastic and steel conveyor pads are

vertically aligned with chain tension

indicator. If conveyor pads hang

no lower than bottom of indicator, no

adjustment is necessary.

c. Listen for unusual noises made

by conveyor motor. If motor grinds,

shut down conveyor hydraulic

circuit and operate manually.

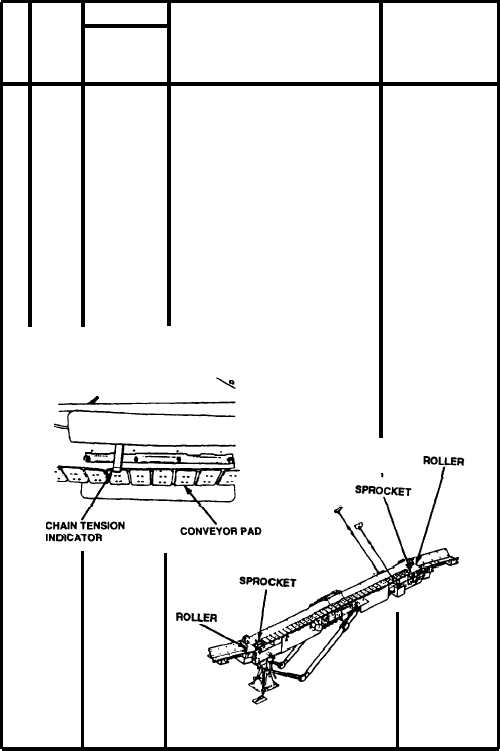

d. Check alignment of conveyor

chain. Chain should be over

sprocket at either end of conveyor

and should be centered with rollers.

2-46

Change 1