TM 9-2350-287-10

Section III. MAINTENANCE PROCEDURES

This section covers maintenance procedures to be performed by the driver and crew. These

procedures are engine cooling system maintenance, servicing of fuel system, refueling,

servicing of batteries, aircleaner maintenance, track maintenance, conveyor speed adjustment,

conveyor chain maintenance, APU maintenance, AFES maintenance, decal maintenance,

strap webbing maintenance, restraining strap maintenance, and MWRH maintenance.

ENGINE COOLING SYSTEM MAINTENANCE

Adding Coolant

WARNING

NEVER remove radiator cap on an overheated engine until

engine has cooled.

NOTE

Overheating is caused by a faulty cooling system or low

coolant level. Proper maintenance of cooling system will

help prevent overheating.

1.

Park vehicle on level ground. Lower the rpm below cruising speed on an overheated

engine until temperature drops to operating range. If temperature continues to rise, shut

down completely and allow 10 minutes for engine to cool before adding coolant.

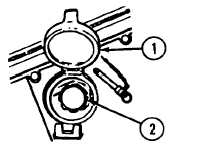

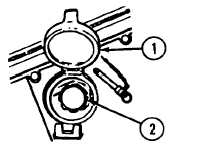

2. Open radiator cap access cover(1). Using

a rag, slowly unscrew radiator cap (2).

When steam subsides, remove cap (2).

3.

Start engine and idle. Add coolant to top

of filler neck and replace cap (2).

4. Run engine for 1 minute longer to

eliminate any air locks; recheck coolant

level and add coolant if necessary.

Faulty Cooling System

If radiator is clogged or dirty, notify Unit maintenance.

Change 1

3-19