TM 9-2350-277-20-2

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS), INCLUDING

LUBRICATION INSTRUCTIONS — Continued

0155 00

ITEM

NO.

INTERVAL

MAN-

HOUR

ITEM TO BE

CHECKED OR

SERVICED

CREWMEMBER

PROCEDURE

EQUIPMENT

NOT READY/

AVAILABLE

IF:

44

Semi-

Annual

Final Drive

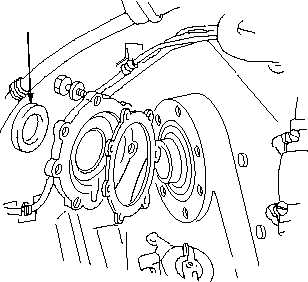

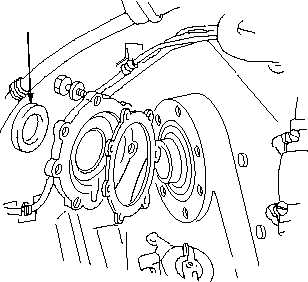

a. Inspect final drive input shaft oil seals for

evidence of leakage. Replace final drive seals

that have leaks (WP 0404 00). Tighten screws to

21-25 lb-ft (28-34 N m) torque. Use torque

wrench (WP 0926 00, Item 79).

Any Class III

leaks.

FINAL DRIVE

OIL SEAL

45

Semi-

Annual

Power Plant

Noises

a. Check power plant operation. If unusual noises

are heard, repair suspect component or contact

higher level of maintenance for assistance and

repair.

46

Semi-

Annual

Exhaust System

NOTE

Carrier leaks exhaust when weather is

cold. For this reason, carbon will be

present around joints and exhaust pipe

connecting clamps. This is normal. The

exhaust system joints will seal after pipes

heat up. Check for exhaust leaks only

after engine reaches normal operating

temperature of 180

to 205

F (71

to 93.3

C).

0155

00-92