LOCATION AND DESCRIPTION OF MAJOR COMPONENTS AND SYSTEMS (CONTINUED)

HYDRAULIC SYSTEM (PRIMARY AND BACKUP)

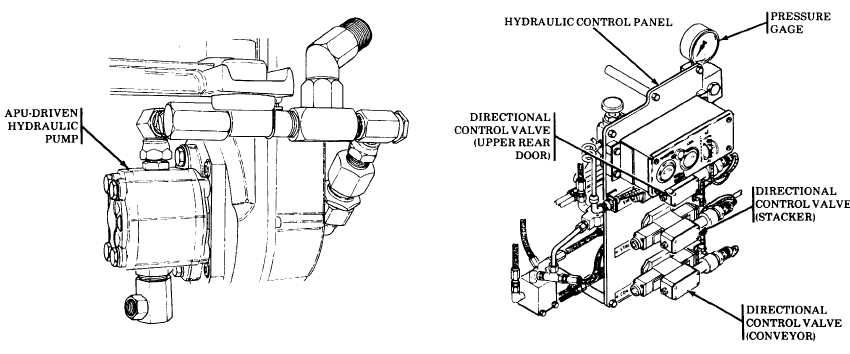

The hydraulic system is used to operate the upper rear door,

stacker and conveyor. The APU is used to drive the primary

hydraulic pump for system operation. The primary hydraulic pump

is capable of delivering 4.5 gallons per minute of flow at a system

pressure of 1550 psi. Hydraulic fluid is pumped from the 13-gallon

capacity hydraulic fluid reservoir to the hydraulic control panel.

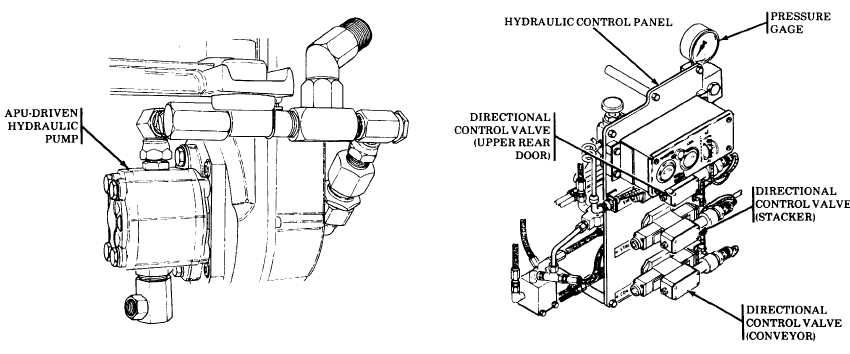

The hydraulic control panel assembly contains three elec-

tromechanically activated directional control valves used to route

hydraulic fluid to the system to be operated. The upper directional

control valve controls the action of the upper rear door actuator, ex-

tending or retracting the actuator to open or close the upper rear

door. The center directional control valve controls the stacker tray

up-and-down movement. The lower directional control valve con-

trols the action of the conveyor motor for forward or reverse travel

of the conveyor. The hydraulic control panel also incorporates a

pressure gage which indicates primary or backup system pressure.

The conveyor control switch actuates the conveyor solenoid at the

conveyor control valve. The rear door switches are located at the

upper and lower left areas of the rear door opening. The stacker tray

control switch is located on the stacker. If there is a failure of the

primary hydraulic system, the system can be operated by switching

to the backup system.

TA312055

1-19

Change 1

TM 9-2350-267-20