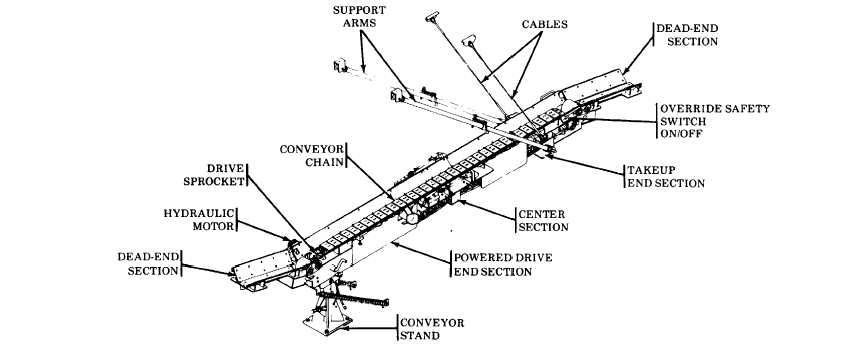

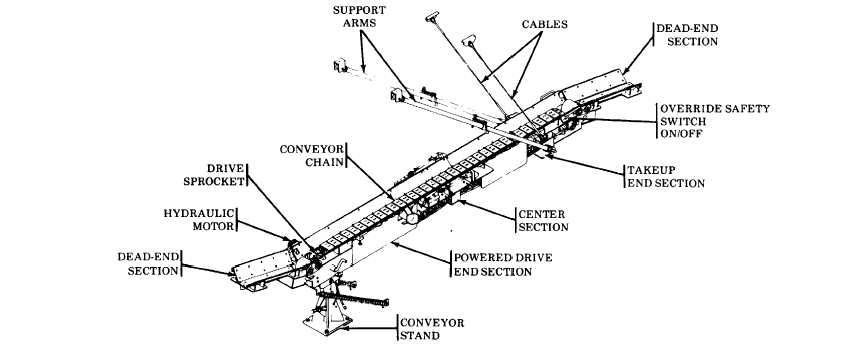

LOCATION AND DESCRIPTION OF MAJOR COMPONENTS AND SYSTEMS (CONTINUED)

CONVEYOR SYSTEM

The conveyor is a hydraulically powered system and can be

operated in either forward or reverse direction. Two stationary

dead-end sections, one at each end, are used as staging areas for am-

munition transfer. The powered parts of the conveyor are: powered

drive end section, center section and takeup end section. A three-

position switch, located on the hydraulic control panel, actuates the

conveyor directional control valve which allows the conveyor motor

to operate in either forward or reverse. A drive sprocket coupled to

the motor shaft moves the conveyor chain.

An override safety (ON/OFF) switch, located at the takeup end sec-

tion, provides an outside vehicle shutoff capability. The chain runs

taut across the top of the conveyor, and loose across the bottom. A

chain adjustment device allows chain tension to be adjusted by

moving the idler sprocket forward or backward. Telescoping sup-

port arms serve to adjust and lock the conveyor in several

operating positions. Two cable assemblies support the conveyor

when deploying the system, and are removed and stowed when the

system is in operation. A hand crank, for manual operation, is pro-

vided in case of a malfunction of the hydraulic system. The con-

veyor can be folded and stowed inside the vehicle when not in use.

TA309937

1-21

TM 9-2350-267-20