SHIPMENT AND STORAGE (CONTINUED)

Prepare flatcar for loading by removing debris, previous blocking, nails and other

obstructions. Inspect flatcar for loose or broken floor planks. If found unsatisfactory,

reject car for use.

If suitable hoisting equipment, permanent loading ramps and handling equipment

are not available for loading or unloading material, improvised runways, ramps and

spanning platforms can be constructed.

Loading must be governed by the capacity and length of flatcars available at time

of shipment, as well as requirements of bill of lading and shipping instructions.

Position vehicle as far from brake wheel end of flatcar as space permits. Provide

minimum clearance of 4 inches below and 6 inches above, behind, and to each side

of flatcar brake wheel.

BLOCKING

General. All blocking instructions specified herein are minimum and are in

accordance with the Association of American Railroads pamphlet Section No. 6

(Rule Governing the Loading of Department of Defense Material on Open-Top

Cars). Additional blocking may be added at discretion of officer in charge.

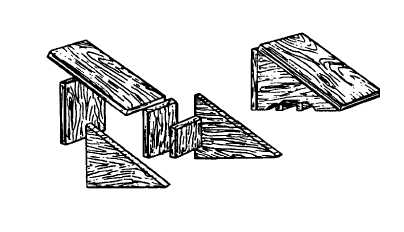

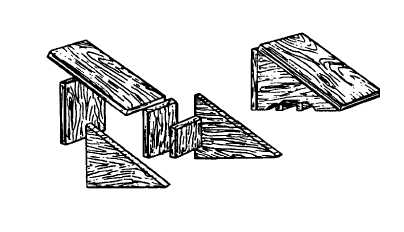

CHOCK BLOCK. Construct for chock blocks: Two to fit angle between tracks

and car deck at front of vehicle, and two to tit angle between track and car deck

at rear of vehicle. Using 1-5/8-inch-thick lumber, make chock blocks 12 inches

wide and minimum of 18 inch high. Nail pieces together with 20-penny nails.

Place one chock block against front of each track, and one against rear of each

track. Toenail check blocks to car floor with 40-penny nails.

CHOCK BLOCK-EXPLODED AND ASSEMBLED VIEWS

TA310399

18-3

TM 9-2350-267-20