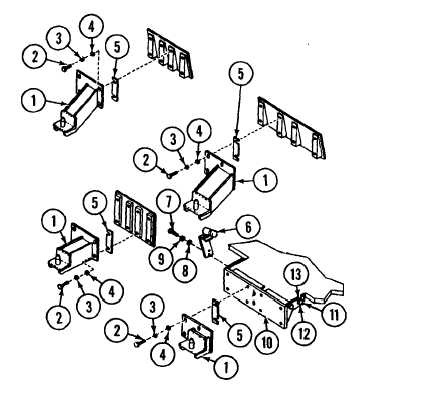

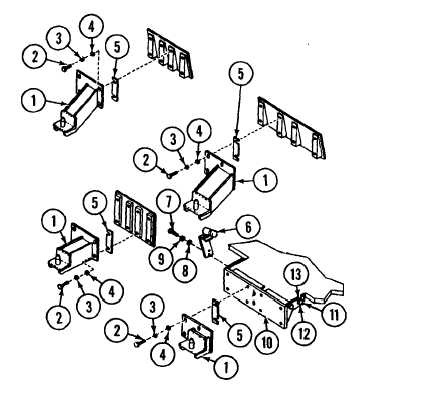

PROJECTILE RACK BASE, SUPPORTS AND VEHICLE WALL-MOUNTED RESTRAINTS REMOVAL AND INSTALLATION (CONTINUED)

INSTALLATION

NOTES

• Aline restraints, supports and adapter with scribe

marks for correcet positioning at installation.

• Apply zinc chromate paste (item 46, Appx D) between

all steel and aluninum mating surfaces.

l Ensure that shims are installed in props number and

location.

A Install rack base (30) on vehicle hull floor with 16 screws (31), 16 new

lockwashers (32), 16 flat washers (33), and 32 flat washers shims(34).

B

Install adapter (23) on vehicle floor with two screws (24), two new lockwashers

(25) and two flat washers (26) from the top; and two screws (27), two new

lockwashers (28), and two flat washers (29) from the end.

C Install right and left rear base supports (19) with two screws (20), two new

lockwashers (21) and two flat washers (2) for each support.

D lnstall right and left front base SUPPOrtS (17), shims (17A) and angles (18) on

vehicle floor with five screws (14), five new lockwashers (5) and five flat

washers (16) for each support.

NOTE

Install correct restraints in marked positions. Install

correct number of shims between each restraint and

bulkhead mounting area.

E

Install bracket (10) on forward bulkhead with four screws (11), four new

lockwashers (12) and four flat washers (13).

F

Install air cleaner indicator and bracket assembly (6) with screw (7), flat

washer (8) and new lockwasher (9).

G Install four rear rack restraints (1) and shims (5) on vehicle wall with four

screws (2), four new lockwashers (3) and four flat washers (4) for each.

11-4.1/11-4.2 blank)

Change 4

TM 9-2350-267-20