|

| |

TM 9-2350-287-34

7-2.

FINAL DRIVE ASSEMBLY REPAIR (continued).

9.

10.

c.

1.

2.

3.

4.

5.

6.

7.

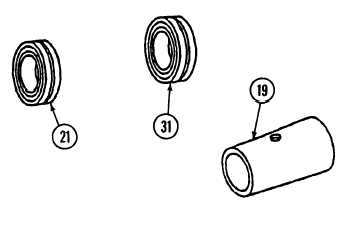

Inspect bearing (21) and bearing (31) (refer

to TM 9-214). Replace if defective.

Inspect spacer (19) for cracks or distortion.

Replace if cracked or if ends are not smooth.

ASSEMBLY

Apply lubricating oil to all threads prior to assembling.

Install two plugs (30) and screws (29) in housing (5).

CAUTION

Make sure all bearings are free from dirt and foreign material. Failure to do so may

cause damage to equipment.

Apply lubricating oil to all bearings.

WARNING

Sealing compound can burn easily, can give off harmful vapors, and is harmful to skin

and clothing. To avoid injury or death, keep sealing compound away from open fire

and use it in a weil-ventilated area. if sealing compound gets on skin or clothing, wash

immediately with soap and water.

Apply sealing compound to outside diameter of new shaft seal (32).

install bearing (31), shaft seal (32), cap (26), and new gasket (27) on output shaft (18).

Using arbor press, install output shaft (18) in housing (5).

install cap (26) on housing (5) and secure with eight new lockwashers (25) and eight screws (24). Torque

screws between 35 and 40 ft-lb (47 and 54 N•m).

7-6

|