|

| |

TM 9-2350-287-20-2

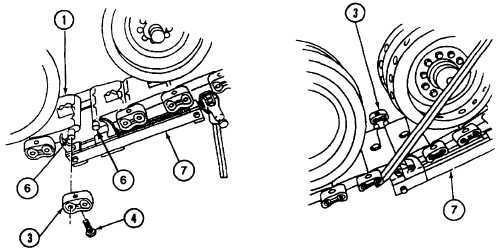

11-13. TRACK SHOE REPLACEMENT (continued).

WARNING

Track is very heavy. To avoid injury, keep hands and feet from beneath track while

it is being lifted.

NOTE

An assistant is needed to lift track end.

5.

Using crowbar, lift end track shoe (1) until it is close enough to other end of track so that two track connecting

fixtures (7) can be installed.

6.

Install two track connecting fixtures (7) on two track link pins (6) and tighten until one end connector (3) will fit

over outside track link pins (6). Tap end connector (3) with hammer until end connector (3) is about one inch

away from track shoe (1).

NOTE

Track can be maneuvered by lifting with crowbar or pushing against inside of track

to bow it out.

7.

Maneuver track until end connector (3) can be installed over two inside track link pins (6). Tap end connector (3)

with hammer until end connector (3) is about one inch away from track shoe.

8.

Remove two track connecting fixtures (7) from track.

9.

Tap two end connectors (3) with hammer to seat end connectors (3) flush with track link pins (6).

10.

Install four new bolts (4) in four end connectors (3). With end connectors (3) at 12 o'clock position over idler

wheel, torque bolts (4) between 380 and 420 ft-lb (515 and 569 N

m) wet.

11.

Mark the end connectors (3).

12.

Drive vehicle for a short distance at a speed not to exceed 10 miles per hour, alternating right and left steers.

13.

Stop vehicle and visually inspect the four end connectors (3) of replaced track shoe. Reposition any end

connectors that have shifted.

14. Torque four bolts (4).

FOLLOW-ON MAINTENANCE:

Adjust track tension (refer to TM 9-2350-287-10).

Change 1 11-31

|