TM 9-2350-287-20-1

TABLE 2-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS) FOR M992A1

ITEM

NO.

23

24

25

26

INTERVAL

A

A

A

A

S=SEMIANNUAL

A=ANNUAL

ITEM TO BE

INSPECTED

ENGINE CRANK-

CASE

ENGINE

TRANSMISSION

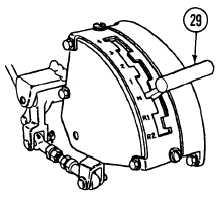

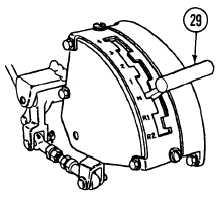

SHIFT CONTROL

LEVER

DECALS, INSTRUC

TIONS PLATES,

STENCIL MARK-

INGS, AND PAINT

PROCEDURE

NOTE

Drain only if directed by AOAP. This

would be done while powerpack is

removed.

a. Drain engine crankcase (only after

operation) (Appendix G).

b. Refill engine crankcase. Drain oil

filter, remove elements, and clean

shell parts. Dry, inspect, and install

with new elements (para 3-8).

a. Groundhop powerpack (para 3-3)

and check for leaks and proper

operation.

b. Perform STE/lCE-R PMCS testing

(para 2-22).

c. Perform STWCE-R tests 10,13, 14

24,24,67, and 71-75.

d. Install powerpack (para 3-2).

a. Move transmission shift control

lever (29) to all positions. Shift control

lever should not bind. If binding

occurs, adjust shift control linkage

(para 8-2).

Replace any decals and instruction

plates, or restencil markings that are

not legible. Clean and paint bare or

worn spots.

NOT FULLY MISSION

CAPABLE IF

a. AOAP requested oil

change.

a. Transmission shift

control lever out of

adjustment, excessively

loose, or binding.

2-28