TM 9-2350-277-34

REPAIR/REPLACE ACCELERATOR STOP SUPPORT ASSEMBLY — Continued

0018 00

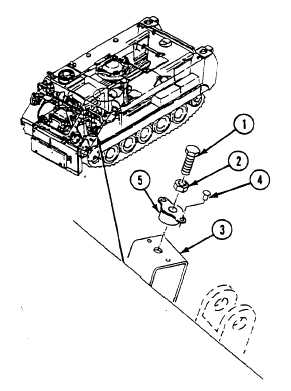

5.

Use a machinist’s hammer and a cold chisel to remove two rivets (4) securing nut (5) to support. Remove nut.

INSTALLATION

NOTE

To install nut (2) only, go directly to Step 4.

1.

Position support assembly (1) on front bulkhead 4-11/16 inches (11.9 cm) from left edge of support to engine

compartment bulkhead. Use straight edge to locate and scribe a line between mounting holes.

WARNING

Unsafe welding practices can cause serious injury from fire, explosions, or harmful agents.

Allow only authorized personnel to weld or cut metals, and follow safety precautions in TM

9-237. Protective clothing and goggles must be worn; adequate protective equipment used, a

suitable fire extinguisher kept nearby; and requirements of TM 9-237 strictly followed.

NOTE

Read (WP 0004 00) before welding.

2.

Weld support assembly (1) to floor plate, using dimensions shown, in accordance with TM 9-237. Use electrode

type 5356.

0018 00-2