TM 9-2350-277-20-1

INTRODUCTION TO HOW TO USE TROUBLESHOOTING—Continued

0005 00

TROUBLESHOOTING BASICS

Troubleshooting Procedure

A troubleshooting procedure serves as a starting point for your troubleshooting work. You will branch in and out of

procedures as you work to find a fault. After correcting the fault, check that the problem has been corrected. The parts of a

troubleshooting procedure are given below.

INITIAL SETUP:

Unit

T

YES

NO

TN

Y

YES

NO

YN

0019 00-1

General mechanics tool kit: automotive

(WP 0926 00, Item 65)

Multimeter (WP 0926 00, Item 30)

Tools and Special Tools

Personnel Required

Maintenance Level

TM 9-2350-277-20-1

Unit Mech 63T10

Helper (H)

References

See your -10

WAIT INDICATOR LIGHT DOESN’T LIGHT

0019 00

Equipment Condition

1. Is MASTER SWITCH ON?

1. Turn MASTER SWITCH ON.

2. Verify no faults found.

1. Replace GLOW PLUG switch

(WP 0209 00).

2. Verify no faults found.

1. Turn MASTER SWITCH OFF .

2. Remove instrument panel for access (WP 0279 00).

3. Remove circuits 406 (1) and 27C (2) plugs from GLOW PLUG

switch jacks (3) and (4).

4. Measure resistance between switch jacks (3) and (4) with GLOW

PLUG switch pressed.

5. Does multimeter read 0 ohm?

Engine stopped (see your -10)

Vehicle blocked (see your -10)

Legend to Sample Above

1 TITLE

This is the name of the procedure that best describes your symptom.

2 INITIAL SETUP

This tells you the tools, materials/parts, personnel, references, and equipment

conditions needed to do the procedure.

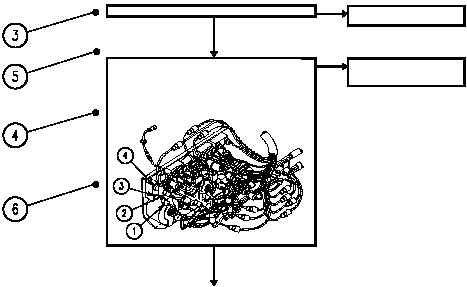

3 TASK STEPS

Step-by-step instructions that isolate the fault.

4 QUESTION

This is last step in YES blocks. The answer to this question will direct you to the

next block.

5 BLOCK ID CODE

These codes identify YES/NO blocks for ease of referencing. When filling out

2028s, list these codes, along with titles and page numbers.

6 ILLUSTRATIONS

These help you locate and identify parts.

0005 00-2