TRANSMISSION SHIFT CONTROL LINKAGE: ADJUSTMENT

B

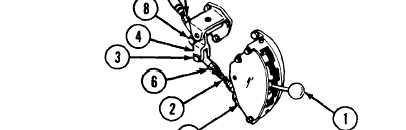

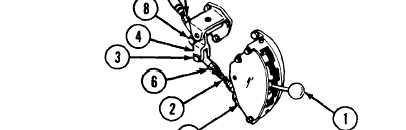

Place bell crank (4) parallel with lever on shift control (5). Loosen

nut (6) and adjust shift control inner rod (2) until clevis pin (3)

can be installed easily. Install flat washer and cotter pin.

Tighten nut (6).

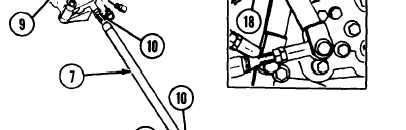

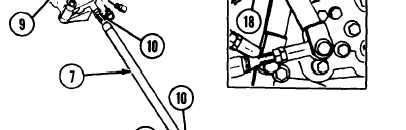

C Disconnect shift control inner tube (7) by removing cotter pin,

flat washer and clevis pin (8). With base lever (9) at neutral posi-

tion on neutral safety switch (verify by attempting to crank

engine after fuel shutoff has been pulled) and with shift lever

in neutral position, loosen nuts (10). Adjust shift control inner

tube (7) until clevis pin (8) can be easily inserted into lever of

inner bell crank (4). Install flat washer and cotter pin. Tighten

nut (10) on shift control inner tube (7).

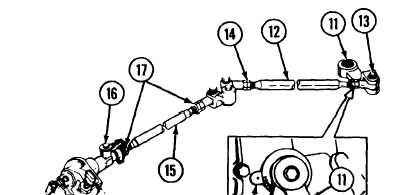

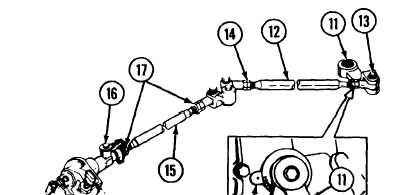

D With shift control lever (11) in neutral (N) position, check in-

dicator (18), disconnect shift control outer rod (12) from

transmission shift control lever (11) by removing cotter pin, flat

washer and clevis pin (13). Loosen nuts (14) and adjust rod to

approximately 8-1/4 inches (centerline of bearing bore to

centerline of bearing bore). Tighten nuts (14).

E

Disconnect shift control outer tube (15) by pulling quick-

disconnect pin (16). Make sure control lever (11) is in neutral

position and install shift control rod (12) in transmission shift

control lever (11). Install clevis pin, flat washer and cotter pin

(13).

F

Loosen nut (17) and adjust shift control outer tube (15) until

quick-disconnect pin (16) can be easily inserted. Tighten nuts

on shift control outer tube.

A

Place shift control lever (1) in neutral (N) position. Disconnect

G Move shift control lever (1) through all positions. In each posi-

shift control inner rod (2) by removing cotter pin, flat washer

tion, check to see that transmission shift control lever indicator

and clevis pin (3) from shift control inner bell crank (4).

(18) indicates the same as the shift control lever position.

TA310446

2-87

TM 9-2350-267-20