TM 9-2350-247-20-1

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS), INCLUDING

LUBRICATION INSTRUCTIONS — Continued

0128 00

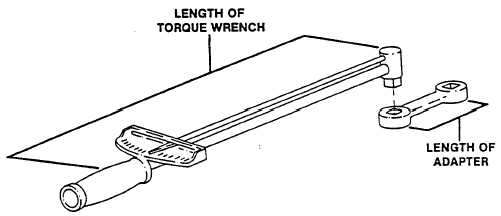

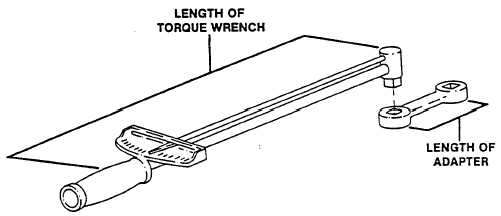

NOTE

The length of the torque wrench is measured from the center of the handle to the center of the

drive. The length of the adapter is measured from the center of the drive to the center of the

wrench.

Corrected reading

=

Required torque value

Length of torque wrench + length of adapter

Length of torque wrench

In the following example, the torque wrench measured 12 inches (30 cm) and the adapter measured 3 inches

(8 cm). From step (4), the required torque is 104 lb-ft (141 N•m).

4) Replace mission track tension adjuster mount screws (1). Tighten loose screws to 130–140 lb-ft (176–190

N•m) torque. Use adapter (WP 0541 00, Item 2) and torque wrench (WP 0541 00, Item 3).

Use 3 inch adapter.

Use 1/2 inch drive torque wrench.

To determine the corrected reading for this task, use the formula:

Corrected reading

=

Required torque value

Length of torque wrench + length of adapter

Length of torque wrench

Corrected reading

=

130 lb-ft

12 inches + 3 inches

12 inches

Corrected reading

=

130 lb-ft

15 inches

12 inches

Corrected reading

=

130 lb-ft

1.25

Corrected reading

=

104 lb-ft

Repeat above steps for other value.

2.

CLEANING

a.

GENERAL. Cleaning is very important. All parts must be cleaned well and kept clean during maintenance. Dirt or

foreign matter can cause malfunctions and equipment failure. General cleaning procedures are detailed in steps b

through n. Special cleaning procedures are covered in the task relating to the specific part.

0128 00-6