5 . Place range selector in N position and

SAMPLING REQUIREMENTS. Samples may

keep engine running.

be taken without WARMING a component to

operating temperature if the equipment has

been operated within the last 30 days. If the

6.

Remove driver's power plant access

equipment has not been operated within the

panel (TM 9-2350-266-10).

last 30 days, the components must be

brought to operating temperature. These

7. With engine running, remove dust caps

requisites apply to both routine and special

from engine and transmission oil sampling

sampling. Oil samples must not be taken

valves.

immediately after oil is added. When oil

sampling valve is not available to take oil

8.

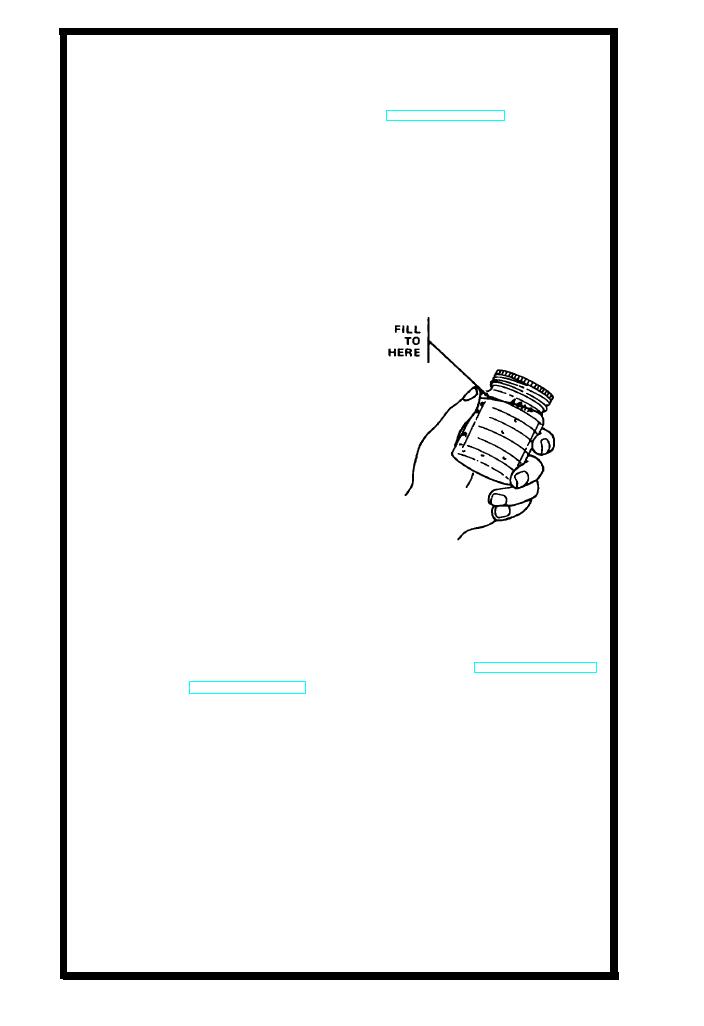

Open sample valve on engine oil filter

sample, use vampire pump to take samples.

and drain small amount of oil into a suitable

container to clear valve of grit and contami-

nation. (Properly dispose of container and oil

SAMPLING PROCEDURES.

upon completion of sample taking.) FiII sam-

pling bottle to neck shoulder and seal it.

Attach DA Form 2026 to sample bottle.

NOTE

DO NOT ADD OIL immediately

prior to taking oil samples.

When Daily operation checks

and services indicate the need

to replenish oil levels, WAIT

until after taking samples. New

oil added immediately prior to

taking samples or before pro-

longed operation of compo-

nents will adversely affect oil

analysis results.

For location of nearest AOAP

laboratory and complete infor-

mation about AOAP, refer to TB

43-0210.

9. Close oil sample valve and reinstall dust

1.

Perform Daily operation checks and

cap.

services.

10. Take oil sample from transmission in

same manner (steps 7 thru 9).

2.

Obtain two sample bottles (NSN

8125-01-082-9697) and two DA Form

2026s from unit AOAP monitor.

11. Shut off engine (TM 9-2350-266-10).

3. Start the engine (TM 9-2350-266-10). If

required (refer to Sampling Requirements),

12.

Install driver's compartment power

operate carrier to bring engine and transmis-

plant access panel and secure carrier.

sion up to normal operating temperatures.

13.

Deliver sample bottles to unit AOAP

4. Stop carrier and set steering levers (TM

9-2350-266-10).

monitor.

Card 2 of 51/(52 blank)