|

| |

TM 9-2350-287-20-2

— KEY —

Lubricants

OE/HDO

(MIL-L-2104D)

LUBRICATING OIL

Internal Combustion

Engine Tactical

Service

OEA

(MIL-L-46167)

LUBRICATING OIL

Internal Combustion

Engine, Arctic

Main Engine

Crankcase

Capacities

38 qt

(35.9 L)

Expected Temperatures

Above 15° F +40°F to -10°F +40°F to -65°F

(Above -9°C) (+4°C to -23°C) (+4°C to -54°C)

Intervals

Intervals are as

follows:

OC -On condition,

or every 25 hours of

operation or 30 days

A - Annually,

Intervals

Intervals

are

based on normal

hours of operation

and moderate

operating condi-

tions.

NOTES:

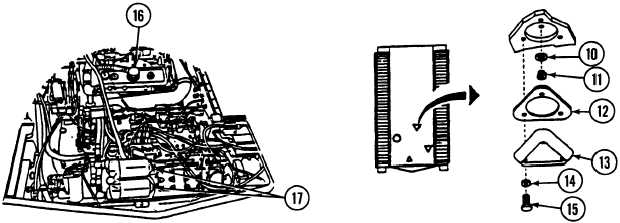

3. TRANSMISSION/MAIN ENGINE AOAP SAMPLER VALVES. Obtain oil sample from transmission and main engine

through AOAP sampler valve after every 25 hours of operation or every 30 days, whichever comes first.

NOTE

When operating in extremely cold temperatures using OEA, this is a semiannual

check.

4. MAIN ENGINE CRANKCASE DRAIN. After operation, park vehicle on level ground (refer to TM 9-2350-287-10).

Remove three screws (15) and washers (14), cover plate (13), and gasket (12) from bottom of vehicle, and remove

drain plug (11) and packing (10) from engine crankcase. After oil is drained, clean drain plug (11) with drycleaning

solvent. Install drain plug (11) and packing (10), cover plate (13), and gasket (12) on bottom of vehicle with three screws

(15) and washers (9). Remove oil fill cap (16) and refill crankcase with oil to “L” mark on dipstick.

5. MAIN ENGINE OIL FILTERS. Drain two oil fitters (17), and remove filter elements (para 3-8). Clean parts with dry-

cleaning solvent. Inspect parts, and replace any parts that appear damaged or unserviceable. Install two oil filters (para

3-8).

G-5

|