TM 9-2350-261-20-1

Table 2-1. Unit Level Preventive Maintenance Checks and Services for M113A2 FOV

Item

Interval

Item To

Procedure

Not Mission

No.

Be

Capable If:

Inspected

62

Semi-

Power

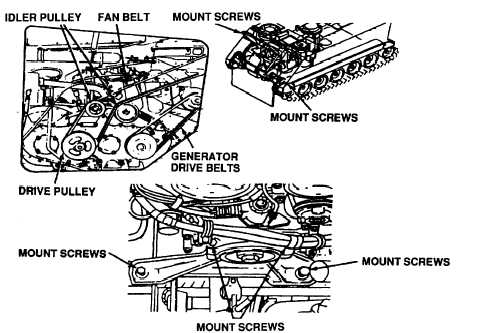

Forward engine mount. Tighten loose

Any cracked or bro-

Annual

Plant

mount screws to 360-420 lb-in (41-48

ken mounts.

Mount

N.m) torque. Use torque wrench (Item

95, Appendix D) and socket set (Item

89, Appendix D).

Tighten loose mount screws to 90-100

lb-ft (122-135 N.m) torque. Use torque

wrench (Item 97, Appendix D).

63

Semi-

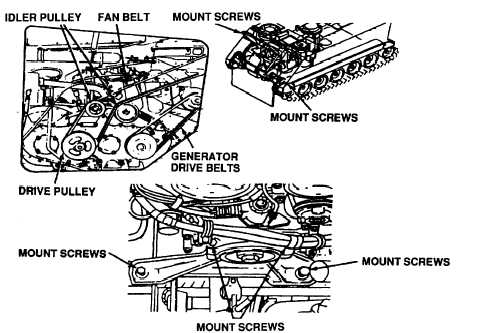

Drive

Check fan belts for proper tension (see

Any belt that is

Annual

Belts

your -10). Adjust, if needed (page

missing,

broken,

8-35).

frayed more than 2",

cracks 1/8” in depth

of 50% of belt thick-

ness.

Check generator drive belts for proper

tension (see your -10).

Adjust, if

needed (page 9-29 or 9-47).

Replace frayed or cracked belts (page

8-35,9-29 or 9-47).

64

Semi-

Cooling

Replace cracked or bent drive pulley

Any cracked, bro-

Annual

Fan

and idler pulley (page 8-41 or 8-37).

ken, loose or miss-

Replace loose/worn bearings (page

ing hardware.

8-46).

Change 3 2-83

CAAAU a u-. -w . v . . ..-.

v-p \-! . ------ . - ---J