TM 9-2350-247-20-1

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS), INCLUDING

LUBRICATION INSTRUCTIONS — Continued

0128 00

SAMPLING PROCEDURES

Perform AFTER operation checks and services. See your -10.

NOTE

DO NOT ADD OIL immediately prior to taking oil samples. When AFTER operation checks

and services indicate the need to replenish oil levels, WAIT until after taking samples. New oil

added immediately prior to taking samples will adversely effect oil analysis results.

Obtain two sample bottles (NSN 8125–01–082–9697) and two DA Form 2026 from the unit AOAP monitor.

Start engine. See your -10 . If required (see Sampling Requirements above), drive carrier. See your -10 to bring engine and

transmission up to normal operating temperatures.

Stop carrier and set the brakes. See your -10.

Place range selector in the N (Neutral) position and keep engine running. On M548A3, lock the steering wheel. See your -10.

Raise crew seat and center floor plate. See your -10.

With engine operating, remove dust caps from the engine and transmission oil sampling valves.

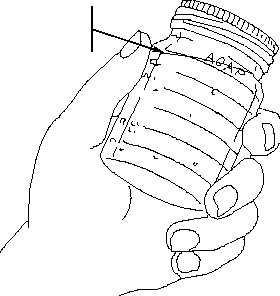

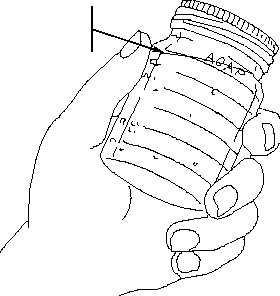

Open sample valve on engine oil filter and drain a small amount of oil into a container to clear valve of grit and

contamination. (Properly dispose of container and oil upon completion of sample taking.) Fill sampling bottle to the neck

shoulder and seal it. Attach DA Form 2026 to sampling bottle.

FILL

TO

HERE

Close oil sample valve and install dust cap.

Take oil sample from transmission in the same manner (see previous three steps).

Stop engine. See your -10.

Lower crew seat and center floor plate. See your -10.

Deliver sample bottles to the unit AOAP monitor.

0128 00-14