|

| |

TM 9-2350-287-34

8-3. IDLER ARM ASSEMBLY REPAIR (continued).

3.

4.

5.

6.

b.

1.

2.

3.

4.

5.

6.

7.

8.

9.

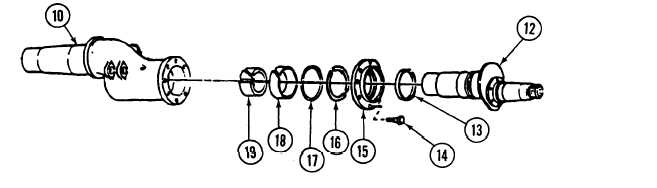

Remove eight screws (14) and spindle (12) from idler arm (10).

Remove inner sleeve bearing (19), outer sleeve bearing (1 8), and preformed packing (17) from idler arm (10).

Discard seal and performed packing.

Using arbor press, compress retainer (15) and spindle (12) together. Remove ring (16) from retainer (15) and

spindle (12).

Remove spindle (12) from arbor press. Remove retainer (15) and seal (13) from spindle (12).

INSPECTION

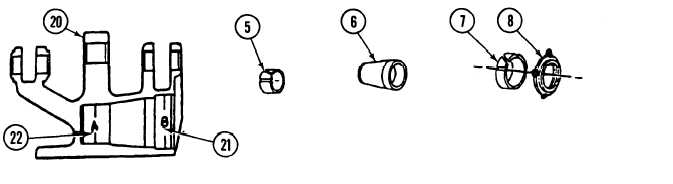

Inspect housing (20) for cracks, breaks, or scoring in bearing surfaces (21 and 22). Replace if defective.

Inspect inner sleeve bearing (5) (refer to TM 9-214).

Inspect bearing spacer (6) for smooth, flat, parallel ends and for cracks or other damage. Replace if ends are

not smooth, flat, and parallel or if defective.

Inspect idler arm retainer (8) for cracks or breaks. Replace if defective.

Inspect outer sleeve bearing (7) (refer to TM 9-214).

Inspect idler arm (10) for cracks, bends, breaks, or scoring. Replace if defective.

Inspect inner sleeve bearing (19) (refer to TM 9-214).

Inspect outer sleeve bearing (18) (refer to TM 9-214).

Inspect ring (16) and retainer (15) for cracks, bends, or breaks. Replace if defective.

8-6

|